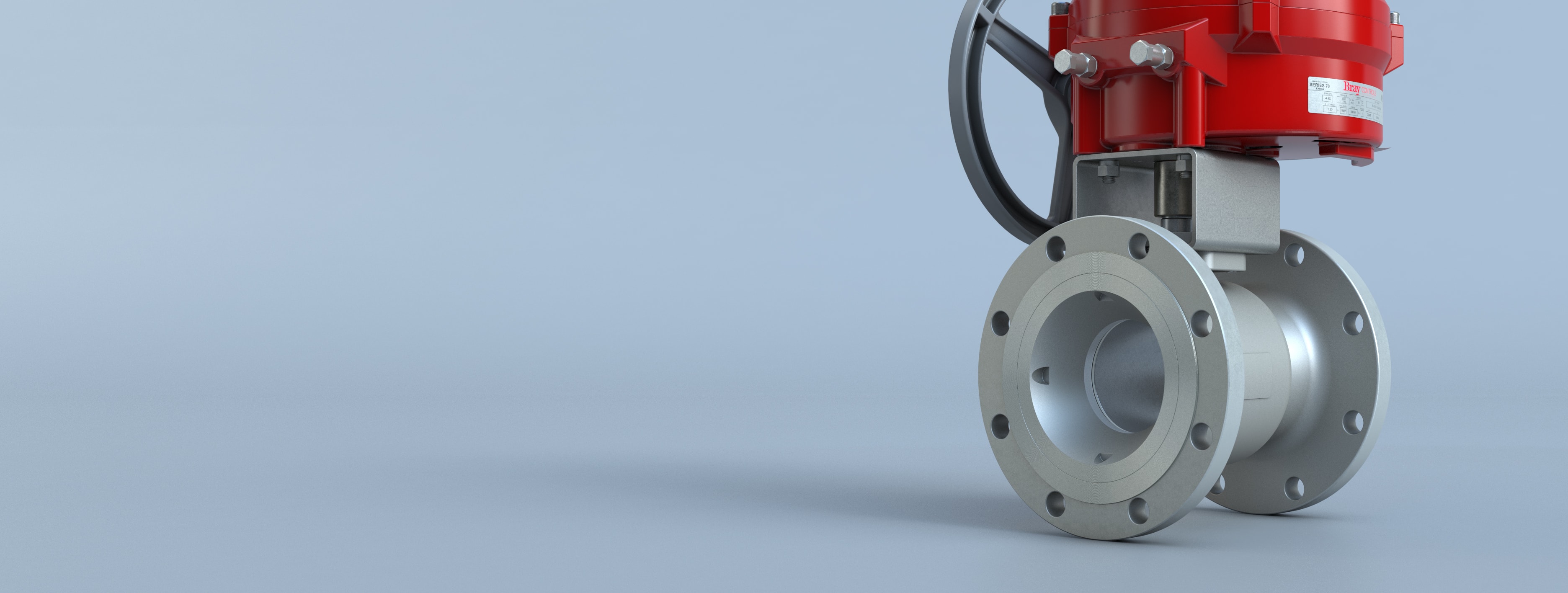

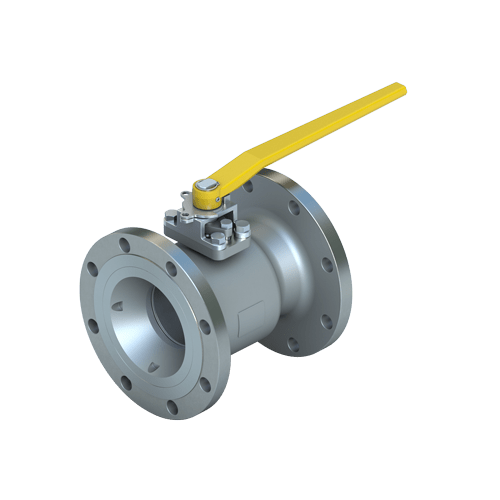

Flanged Ball Valve

Series RF15/RF30

Size Range

NPS 1 to 12 / DN 25 to 300

Temperature Range

-50°F to 650°F (-46°C to 343°C)

Maximum Allowable Operating Pressure

RF15: ASME Class 150

RF30: ASME Class 300

Specifications

Flanged Ball Valve - Series RF15/RF30

Size Range

NPS 1 to 12 / DN 25 to 300

Body Materials

Stainless Steel (CF8M), Carbon Steel (WCB), Special Alloys

Temperature Range

-50°F to 650°F (-46°C to 343°C)

Stem Materials

ASTM A479 Gr 316, 17-4PH, Monel

Maximum Allowable Operating Pressure

RF15: ASME Class 150

RF30: ASME Class 300

Seat Materials

Standard: TFM 1600

Optional: Tek-Fil®*, PEEK, UHMWPE, RPTFE, Metal

Shutoff Rating

ASME Class VI with Zero Leakage

Ball Materials

Stainless Steel (CF8M)

Design Standard

ASME B16.34, API 608, MSS SP72, NACE MR0175

Testing Standard

API 598, ASME B16.34, MSS SP 61

Certifications

API 607, ATEX, CRN, NSF 61/372, PED, PE(S)R, TR CU, SIL

Flange Drilling

ASME B16.5

applications

Process, Tank Farms, Fueling, Oil & Gas

The Series RF15/RF30 raised face flanged ball valves are used worldwide for reliable general purpose flow control applications. With the availability of a wide variety of optional trims and accessories, these versatile raised face flanged reduced port ball valves provide exceptional value and dependable operation across a wide range of service conditions in every industry.

Series RF15/RF30 reduced port flanged ball valves are engineered to ensure bubble-tight shutoff and low operating torque. ½” – 2” sizes feature Flow-Tek's Smart Stem technology with integral live load packing. 2 ½” – 12” valves utilize an independent packing gland which can be easily adjusted without removing mounting hardware or operator. The packing gland is contoured to uniformly distribute the load across the packing. The live load packing is self-adjusting due to its Belleville washers allowing it to compensate for environmental changes and wear, ensuring maintenance free operation and long cycle life. 12" valves feature a trunnion-type ball support to reduce operating torque.

All resilient seat materials ensure bi-directional, bubble tight sealing and feature relief slots on the seat outer diameter to relieve pressure past the upstream seat in case of an upset situation such as trapped gas in the valve body as well as positive preloading to ensure low pressure/vacuum sealing capability.

Non-Fire Safe and API 607 Fire Safe Valves:

Series RF15/RF30 valves are available as non-fire safe with standard stem seals or fire safe to API 607 with graphite stem seals.

Secure Mount

Series RF15/RF30 valves offer ease of automation due to an integrally cast actuator mounting pad that complies with ISO 5211 through 2” valve sizes.