Segmented Ball Valve

Series 19/19L

EN 1092 PN 10, 16, 25, 40

Specifications

Segmented Ball Valve - Series 19/19L

Others available upon request

EN 1092 PN 10, 16, 25, 40

Metal Seat: (316) Stainless Steel with Stellite Hard Facing (S19 & S19L)

Solid Tungsten Carbide (S19L)

Soft Seat: Class VI per IEC 60534-4 / ANSI / FCI 70-2

S19L: CF8M with proprietary hard face coating.

Seat leak – ANSI FCI 70-2

Flangeless: Bray Internal Standard

Features & Benefits

Bray's Series 19L segmented Control Ball Valve combines the versatile design of the standard Series 19 with advanced trims for highly abrasive slurry and severe service applications that often lead to erosion in traditional valves. Bray's proprietary advanced coating technology is applied to the internal components of the valve to provide increased hardness and bond strength over other commonly used coating technologies throughout the industry. Series 19 & 19L segmented valves are available in a variety of trim configurations for use in a wide variety of industries including:

-

Pulp & Paper

-

Sugar & Ethanol

-

Refining Process Control

-

Power Plants

-

Hydromet Pump Isolation

-

Process Control

-

Food & Beverage

-

HVAC

-

Solvent Extraction

-

Mining

-

Water & Wastewater

-

Oil & Gas

-

Chemical

-

Gas Collection Fields

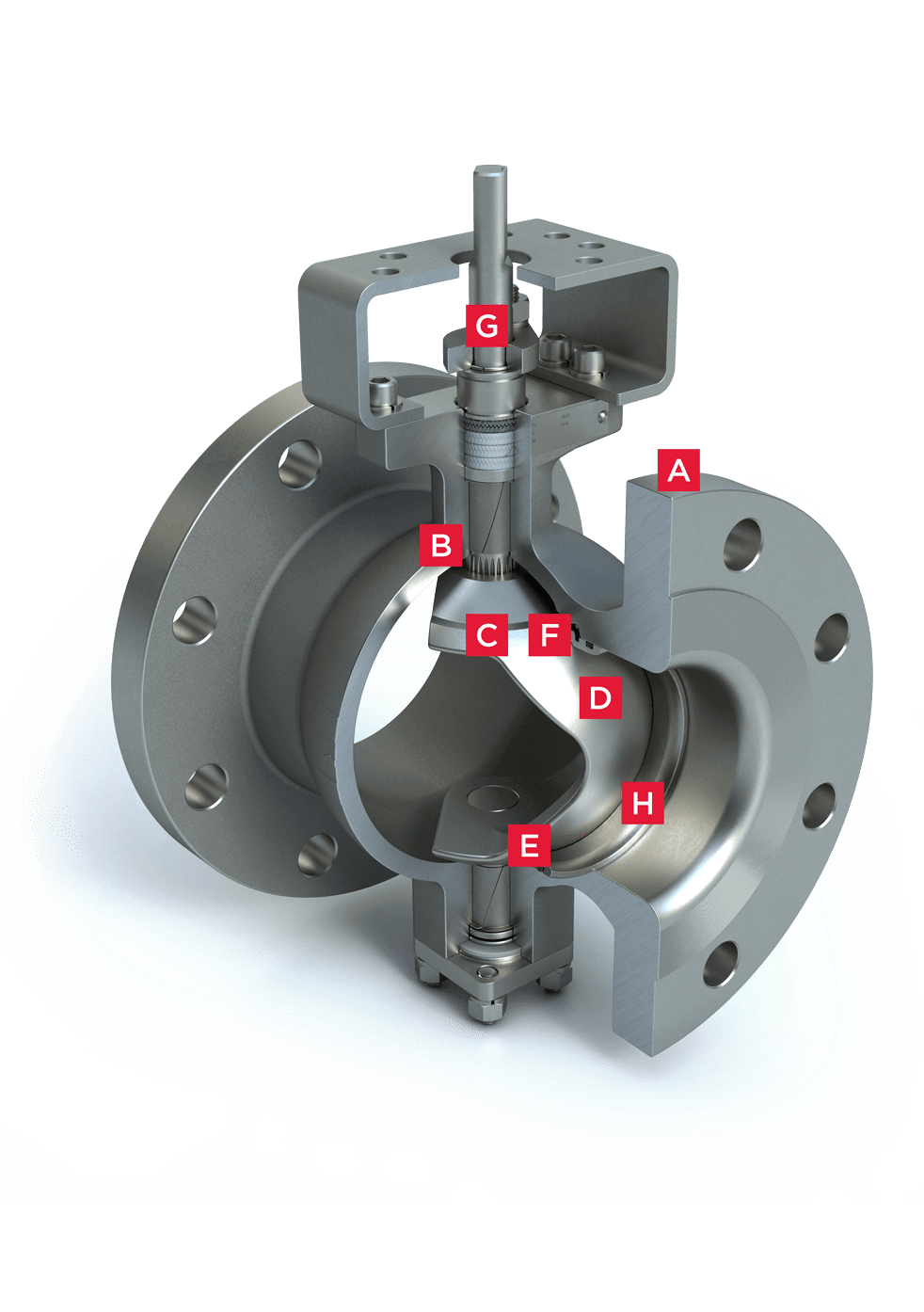

Series 19

The perfect control ball valve solution for slurries containing suspended solids or fibers. viscous fluids, pulp, paper, chemical, wastewater sludge, and other challenging service conditions.

-

A. One-Piece Body

Provides a rigid, robust shell capable of withstanding pipe loading, and eliminates potential leak paths.

-

B. Splined Stem to Segment Connection

Provides efficient torque transmission and precise control, with low hysteresis and reduced deadband.

-

C. Self-Centering Ball Segment

Perfectly oriented, specially designed shaft pin facilitates self-alignment of the ball segment, while simplifying assembly and disassembly during routine maintenance.

-

D. Coatings

High-performance coatings on internal components ensure long life and corrosion resistance.

-

E. Energized Seat

Seat spring provides constant force on the seat to seal against the segment at low differential pressures. At higher differential pressures, optimized sealing diameters ensure lower seat torques.

-

F. Protected Sealing Area

Seats are designed to direct media flow away from the sealing area.

-

G. Blowout Proof Stem

Retaining ring fits between machined stem groove and gland retainer step.

-

H. Easy Maintenance

The seat is replaceable without removing the segment and shaft.

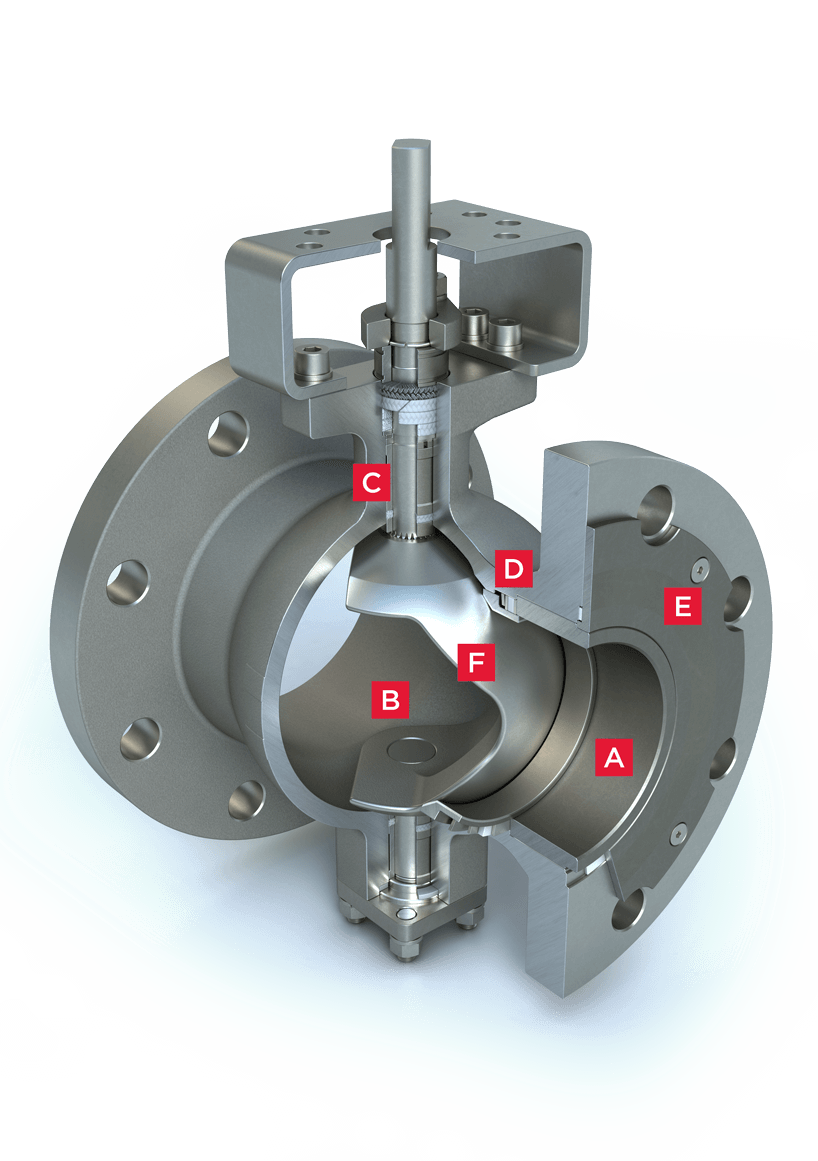

Series 19L

Severe erosion demands more from your flow control valve. In addition to the benefits of the standard service valve, the S19L offers advanced material selections and multiple trim options to provide an application-specific solution for your unique needs.-

A. Erosion Resistant Downstream Liners/Seats

Reverse flow direction prevents body wall erosion due to high velocities at low openings.

-

B. Severe Service Coatings

Customized ultra-hard coatings provide application-specific corrosion and erosion resistance for valve internals.

-

C. Bearing Seals

Protects metal bearings from ingress of media.

-

D. Pressure Balanced Seat Design

Seats capable of sealing under full differential pressures with low torques and smooth operation.

-

E. Easy Maintenance

Flanged retainer with uninterrupted gasket surface provides easy access for seat and liner replacement.

-

F. Trim Options

Multiple options available for optimized performance in various levels of erosive services.