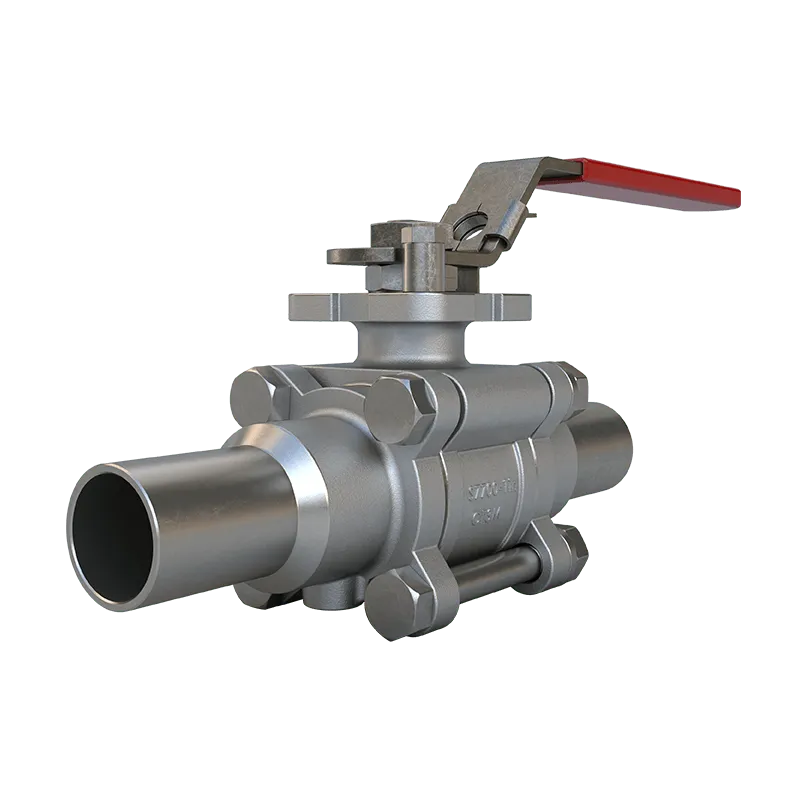

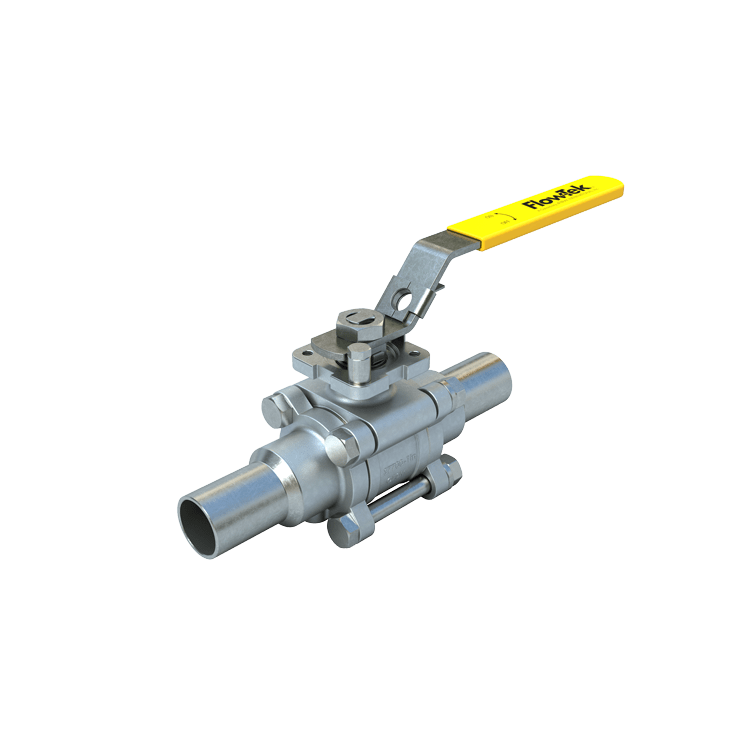

Micropure 3-piece ball valves with electropolished 15 Ra-20 Ra surfaces, FDA approved PTFE seats with extended tube or quick clamps.

Overview

Food & Beverage Industry

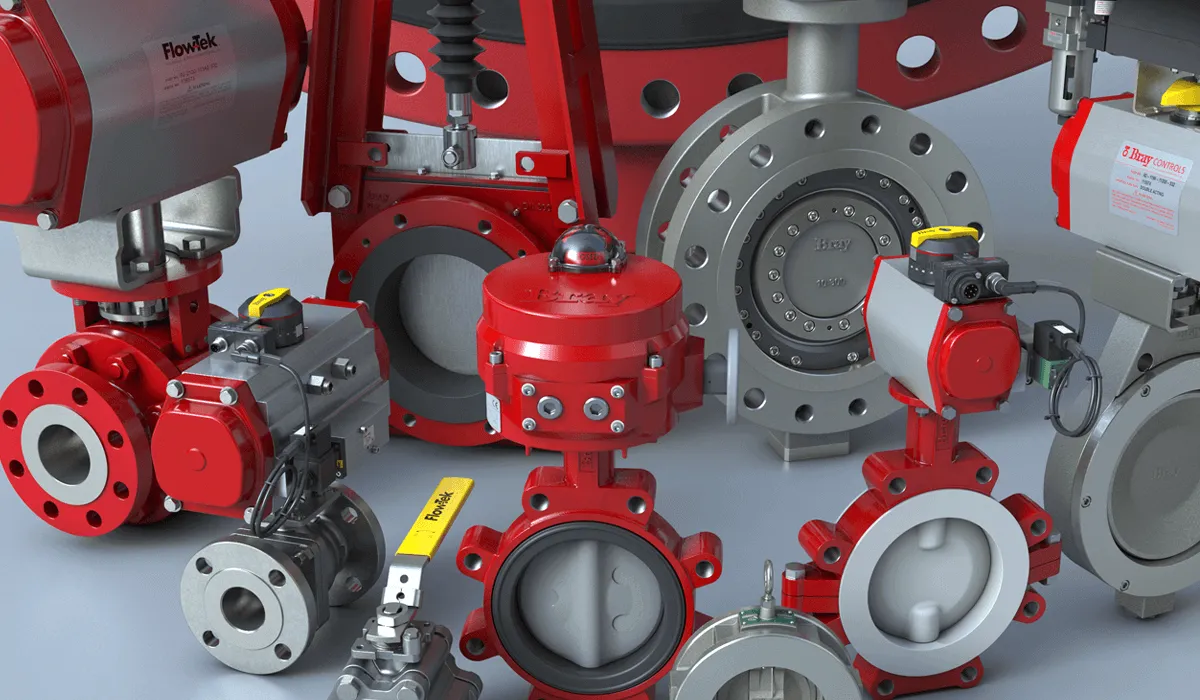

Bray solutions for

Food & Beverage

-

Milk & Dairy

-

Baked Goods

-

Candy

-

Coffee

-

Steam Peeling

-

Frozen Foods

-

Alcohol

-

NSF-61 Approved

-

Quick Clamp Fittings

-

Extended Welding Tube

-

Electropolished Internals

-

Body Cavity Fillers

-

FDA Approved PTFE Seats & Seals

-

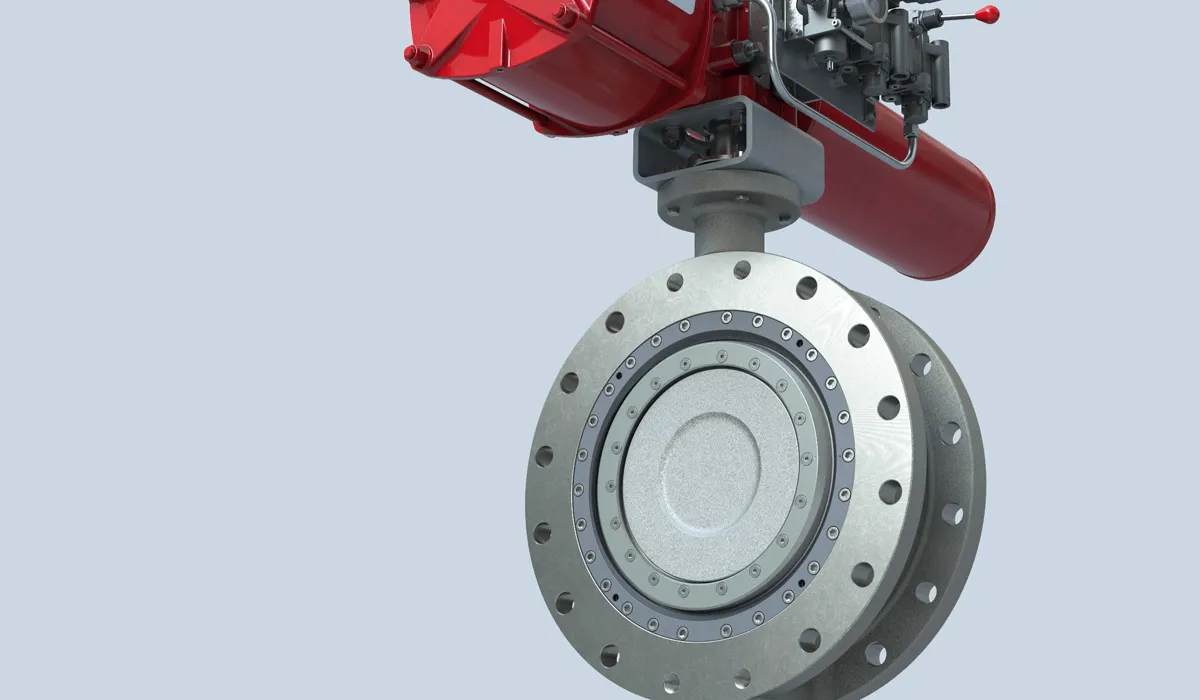

TFM Liners for Butterfly Valves

-

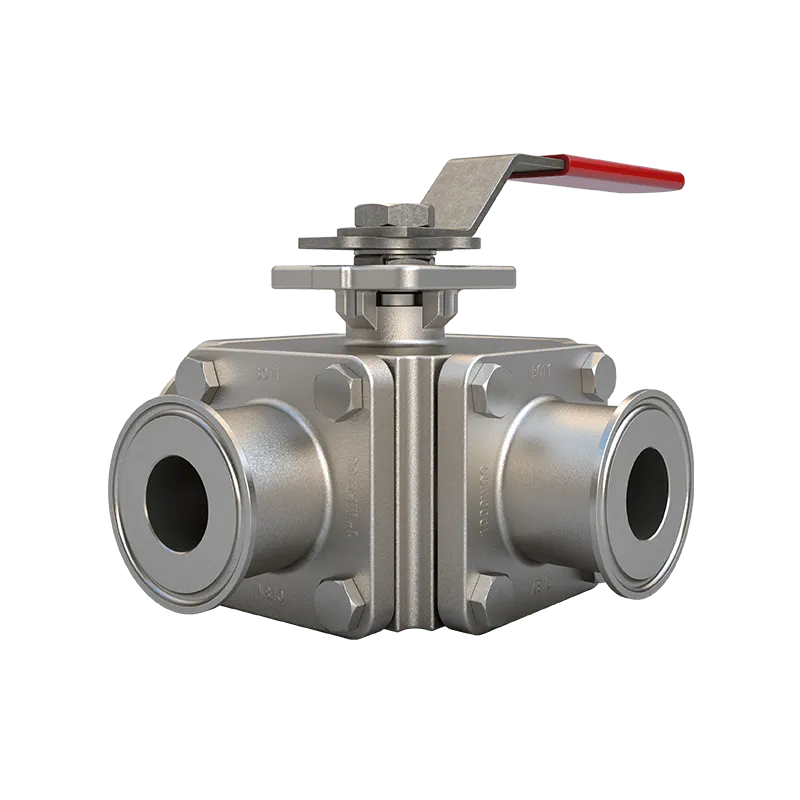

Multi-port Valves

-

Custom Valves

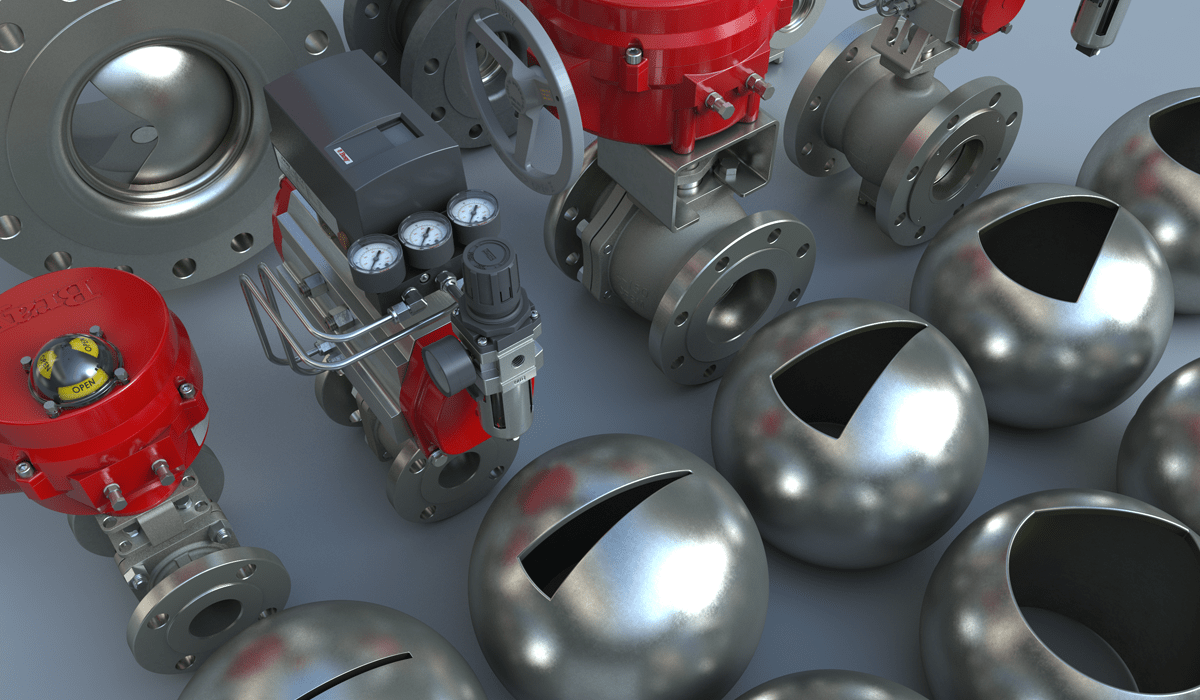

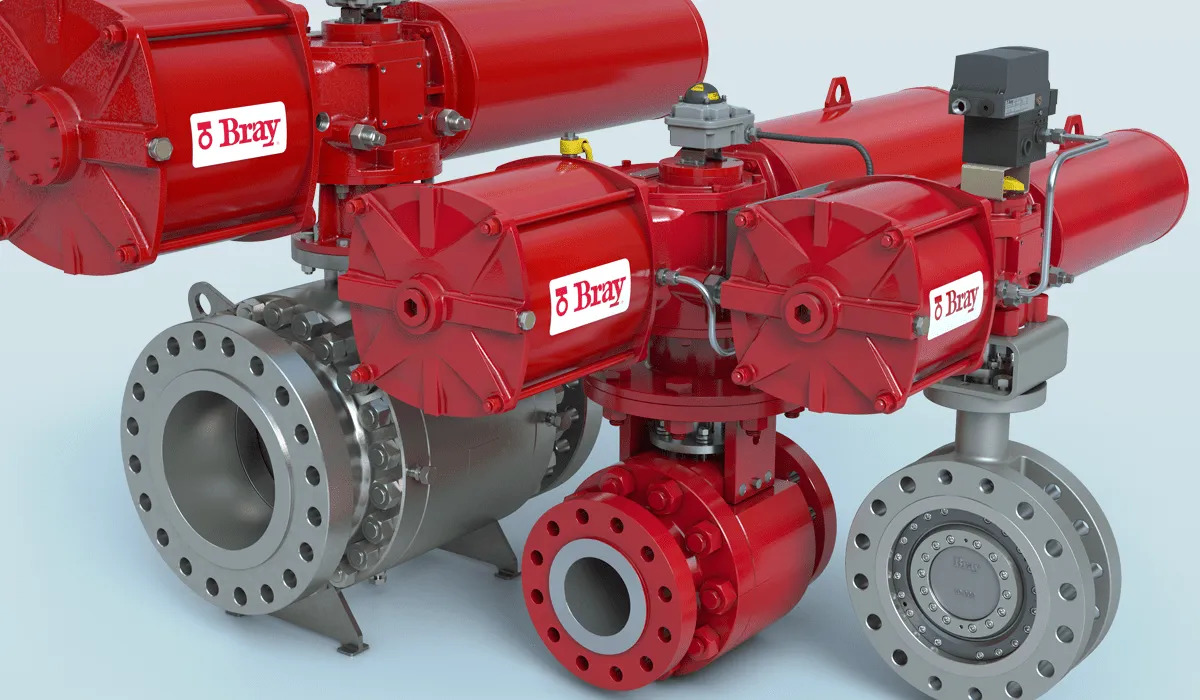

Bray Solutions for

Sanitary Valves

Bray solutions for

Utility Valves

Bray solutions for

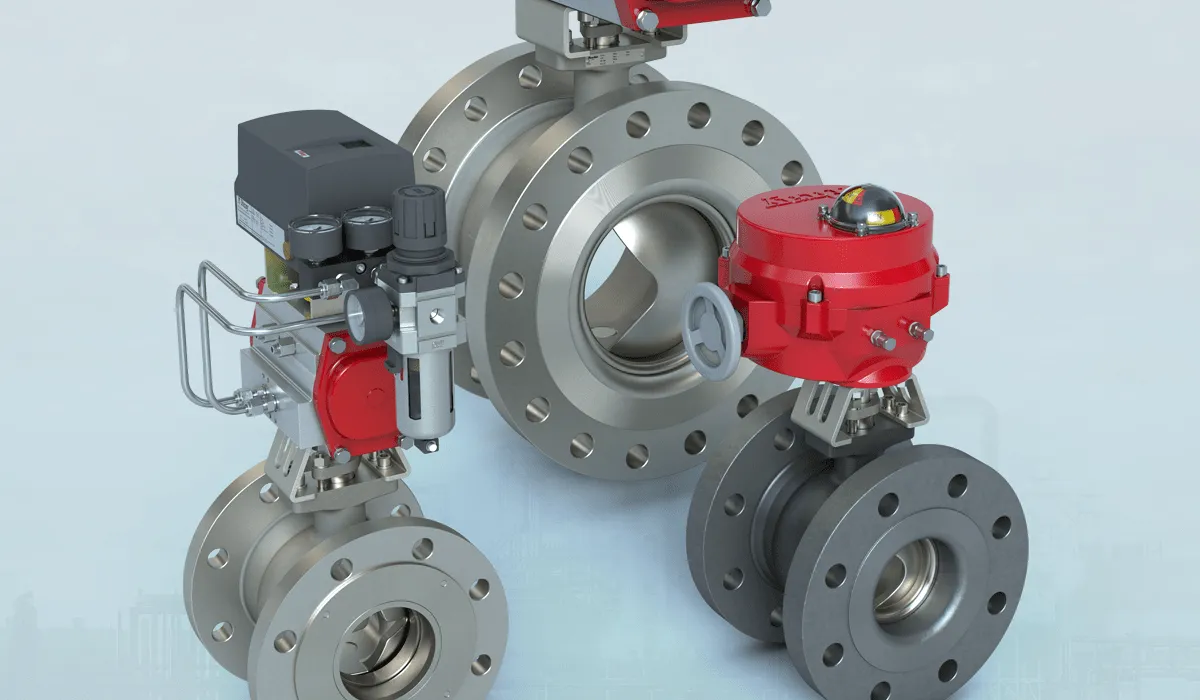

NSF-61 Water Valves

Bray is committed to delivering high quality valves certified to NSF/ANSI/CAN 61 and NSF/ANSI/CAN 372, while also meeting the requirements of the U.S. EPA’s Safe Drinking Water Act (SDWA). Bray’s NSF certified butterfly and ball valve products have passed a rigorous certification program involving product testing, material verification, and annual manufacturing site. Our NSF-61 Certified valves guarantee compliance with safe levels of lead and other harmful contaimnate, ensuring safe drinking water used in food and beverage plants.

Bray International is dedicated to providing customers with top-of-the-line control valves that meet the highest industry standards for safety and quality. Our valves are certified to NSF/ANSI/CAN 61 and NSF/ANSI/CAN 372 standards, ensuring compliance with the U.S. EPA's Safe Drinking Water Act (SDWA). Our NSF-certified butterfly and ball valves have undergone a rigorous certification process, including product testing, material verification, and annual manufacturing site inspections. This guarantees that our valves comply with safe levels of lead and other harmful contaminants, ensuring the safety of drinking water in food and beverage plants. With Bray, you can trust in our commitment to delivering reliable, high-quality valves that meet the most stringent industry standards.

Insights

Learn more about how Bray can transform and help your company

Cleanroom Valve Services

Bray's state-of-the-art cleanroom facilities deliver ISO Class 6 to ISO Class 9 precision cleaning around the globe where valves are cleaned, inspected, bagged & tagged to meet the most stringent global standards, ensuring contamination-free valves.

Certified and Trusted

By thousands of companies worldwideOur performance tested products are in compliance with a variety of global certifications and approvals, including FDA, EFSA, NSF, Lloyd's Register, UL, and more.

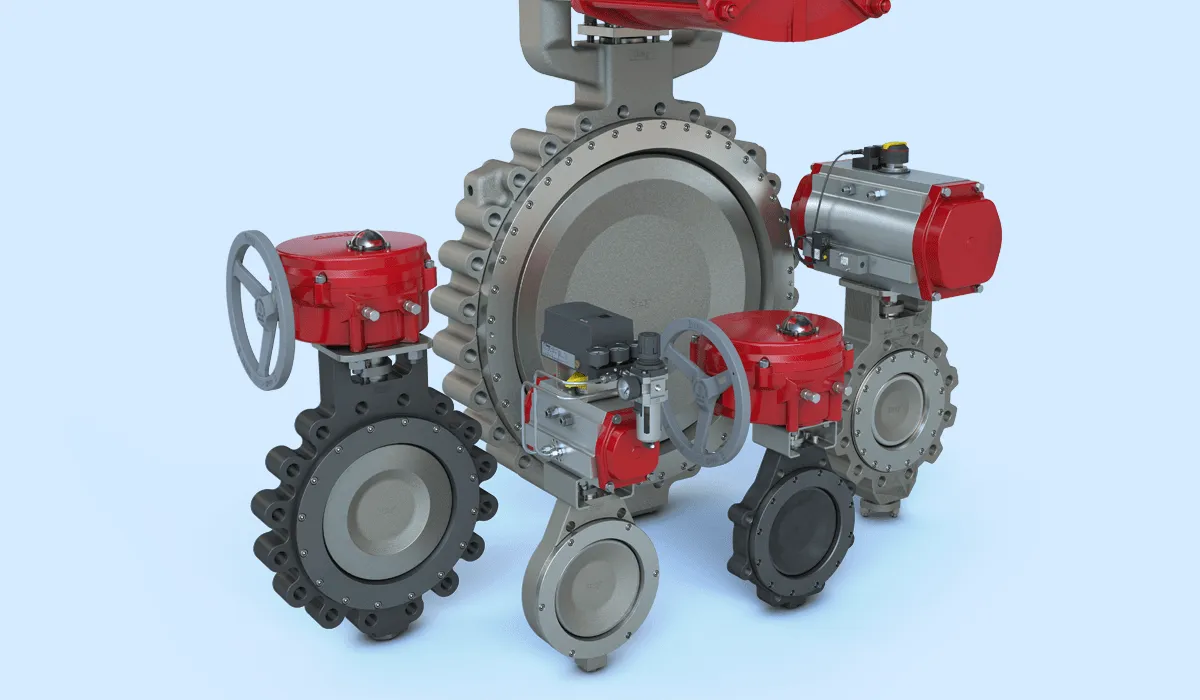

Valve Solution for Food & Beverage

Discover all products that can be applied for Food & Beverage

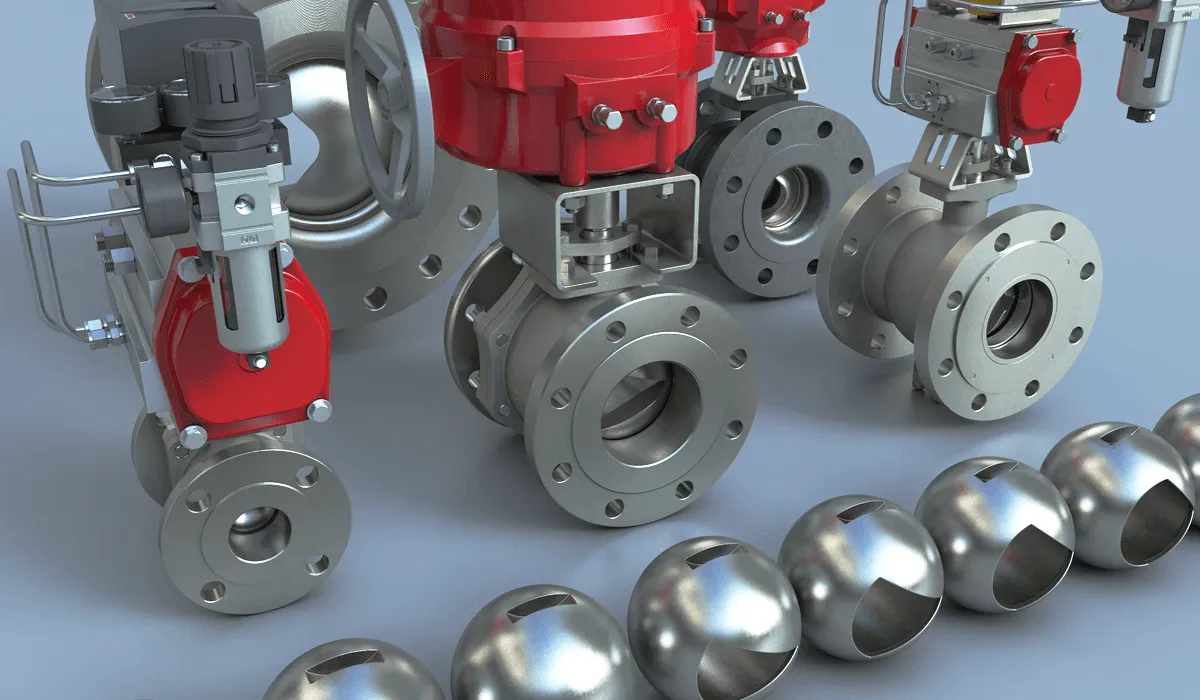

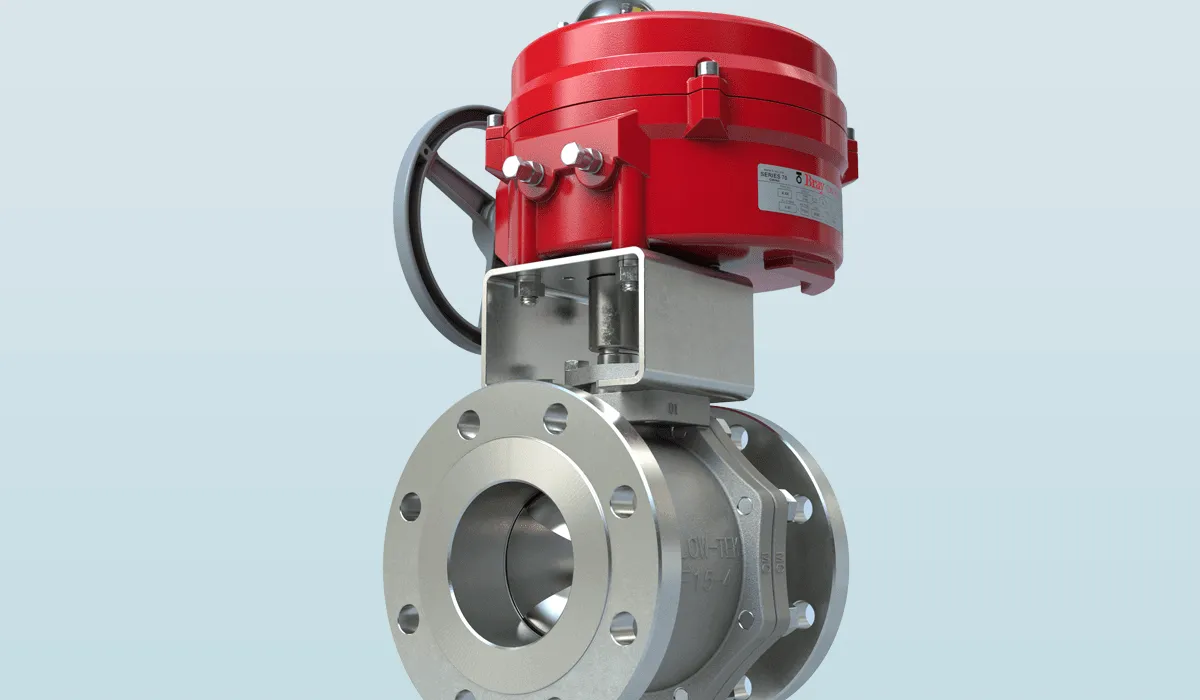

3-Piece Ball Valve

Series S7500/S7700 Micro Pure3-Piece Ball Valve

Triad Series3-Piece Ball Valve

Series DM7000/DM80003-Piece Ball Valve

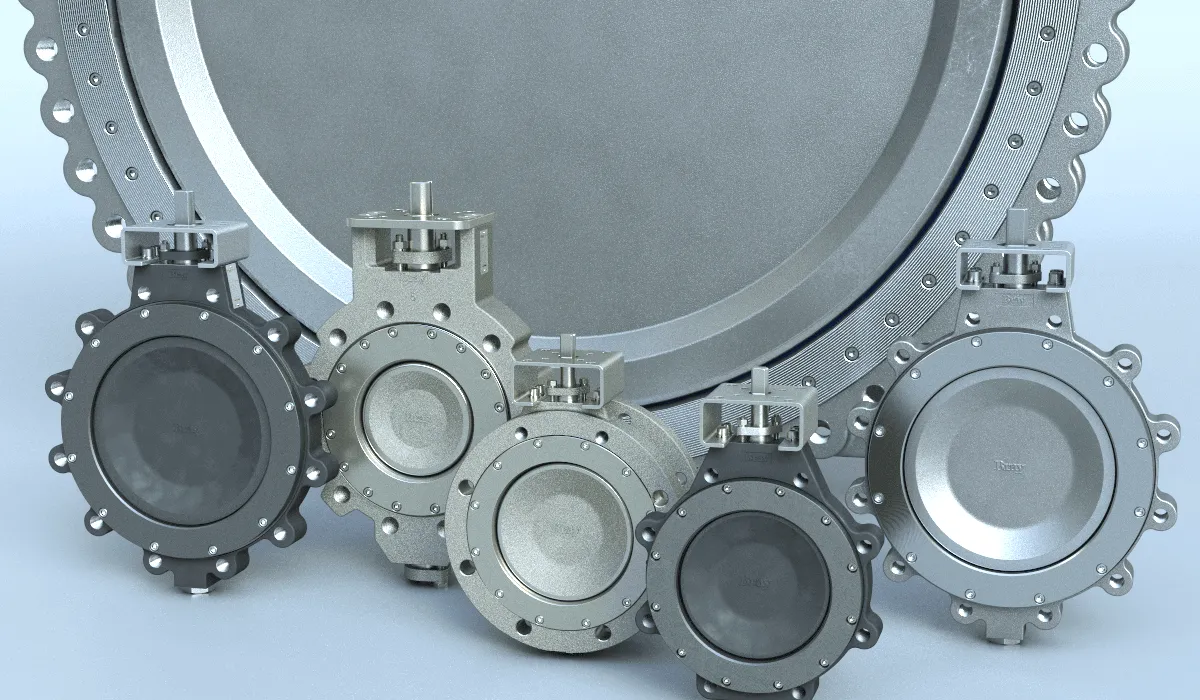

Tank SeriesResilient Seated Butterfly Valve

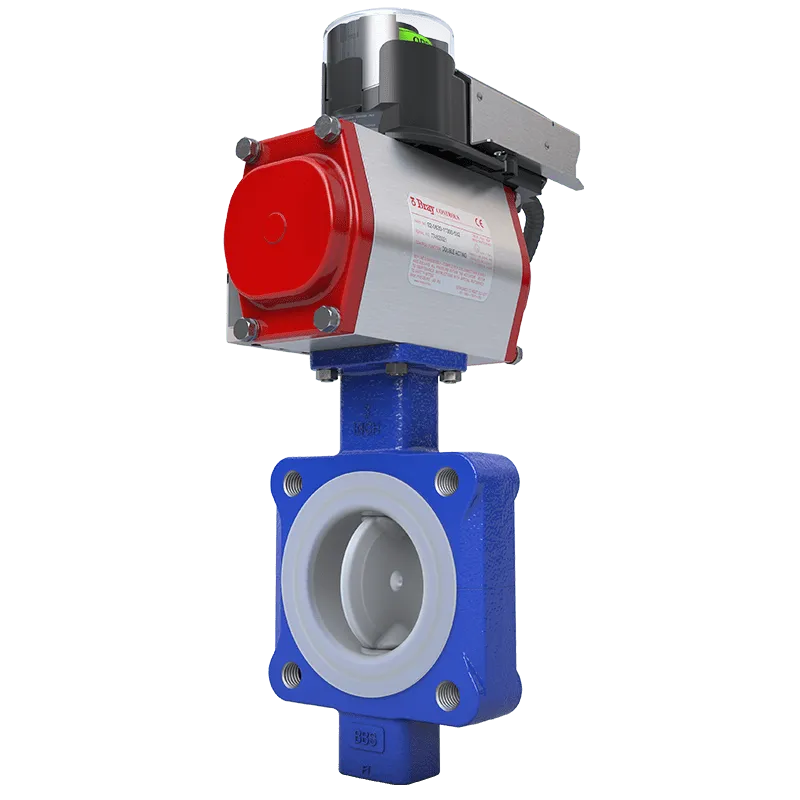

Series 20/21PTFE Lined Butterfly Valve

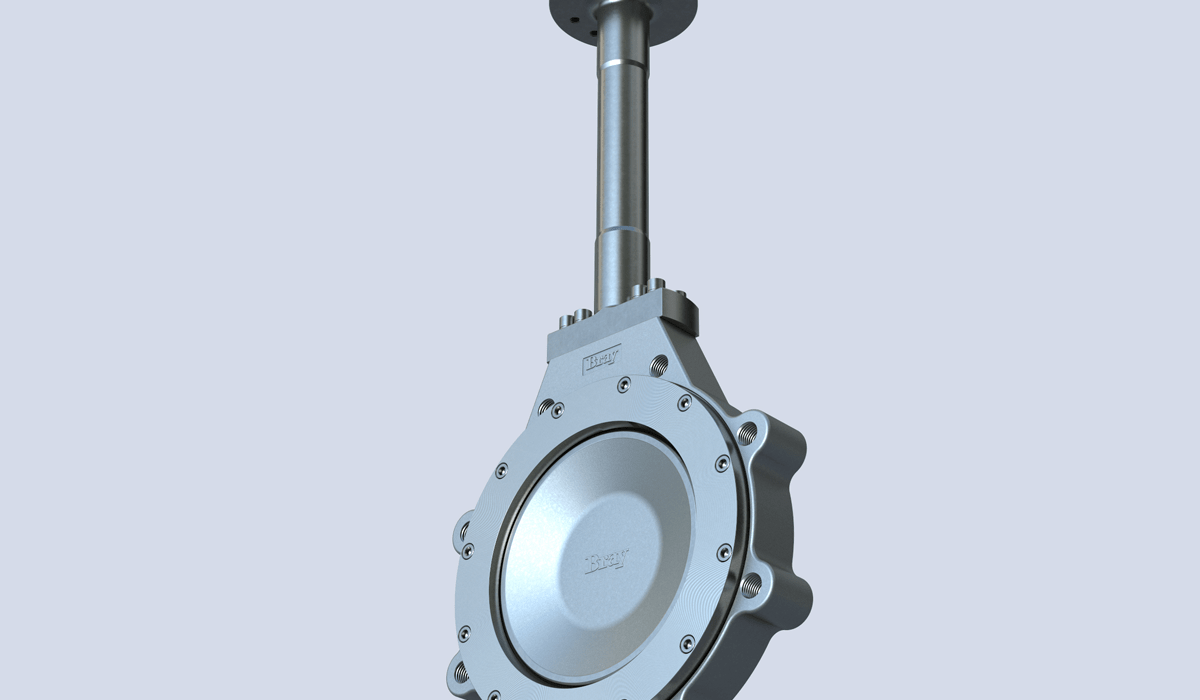

Series 22/23Bidirectional Knife Gate Valve

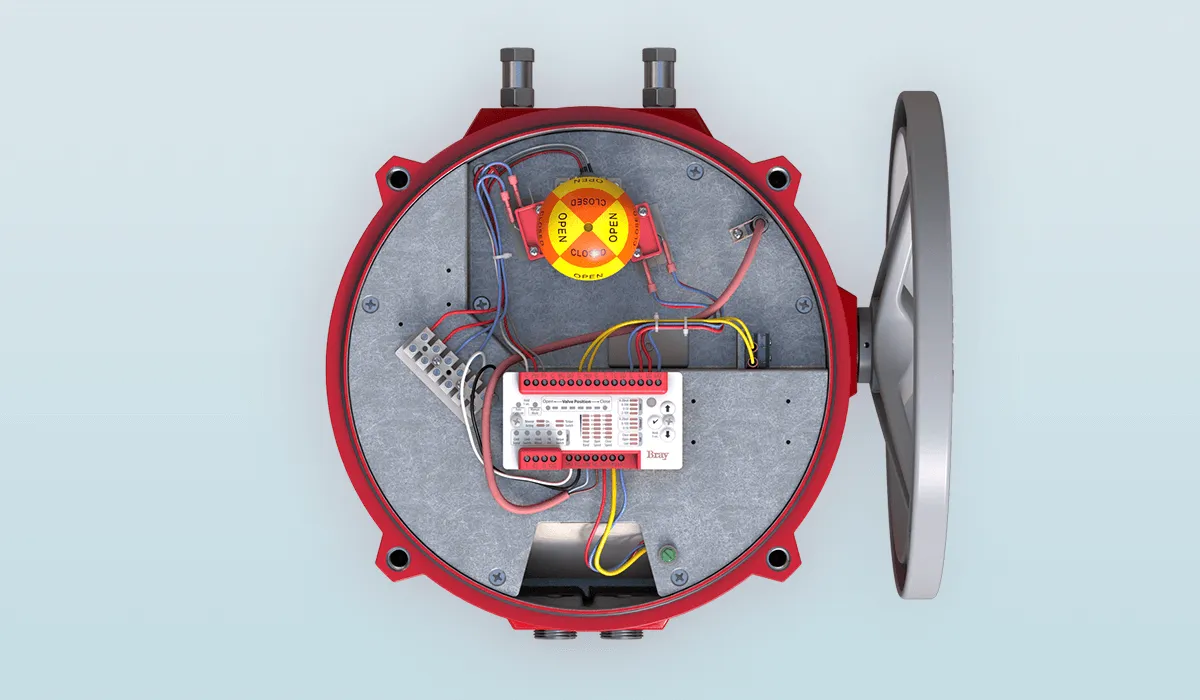

Series 740Rack and Pinion Pneumatic Actuator

Series 92/93