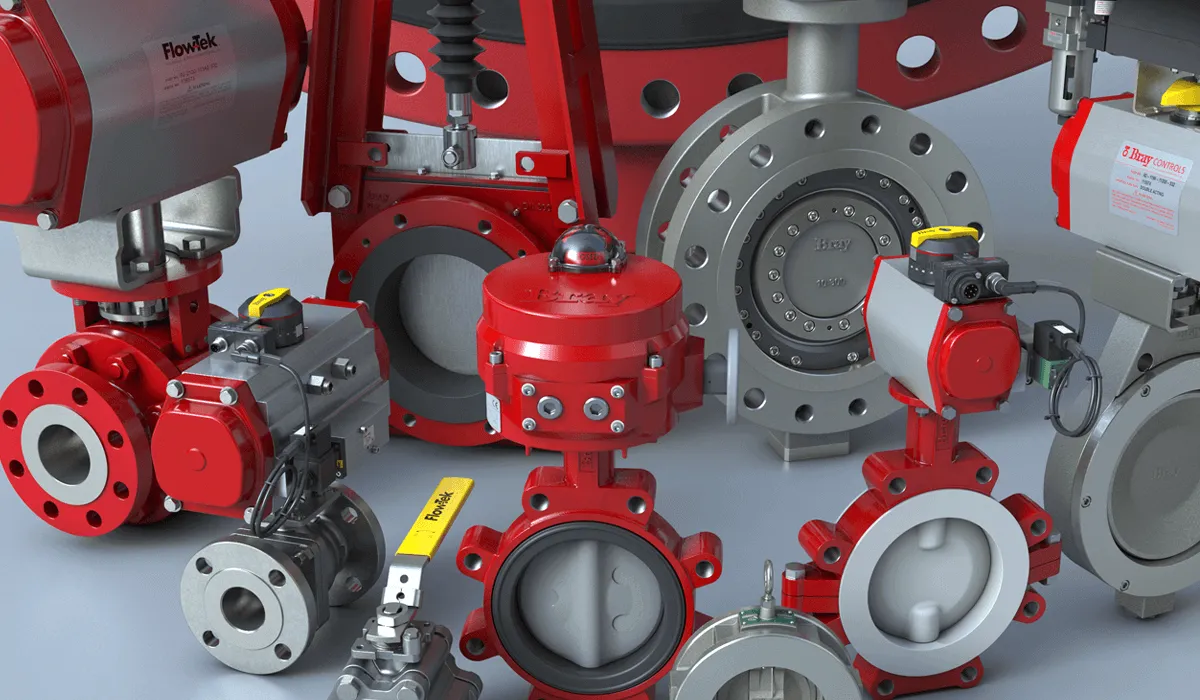

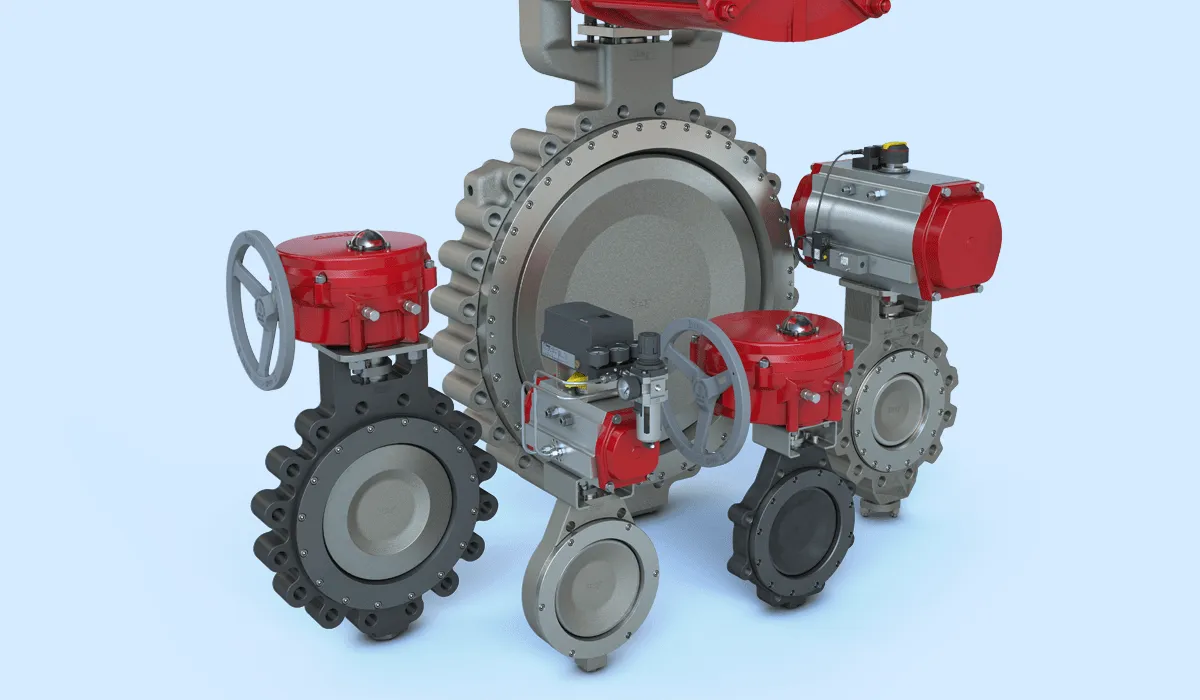

The chlor-alkali process is an industrial method for the electrolysis of sodium chloride solutions. The majority of the worlds chlorine production is accomplished by an electrolysis reaction that splits the saturated sodium chloride brine into chlorine gas, hydrogen gas and caustic soda (sodium hydroxide - NaOH). Bray manufactures valve solutions for each phase of chlorine processing engineered for the aggressive corrosion and scaling of salts, chlorine, concentrated caustic soda and hydrogen gas.

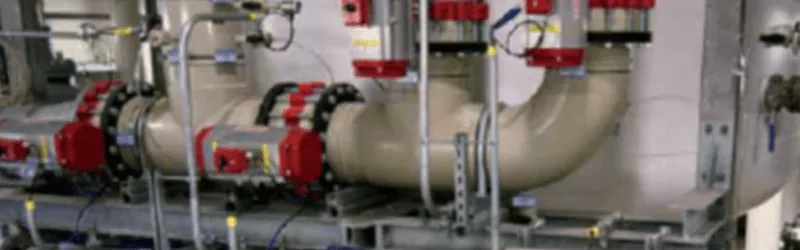

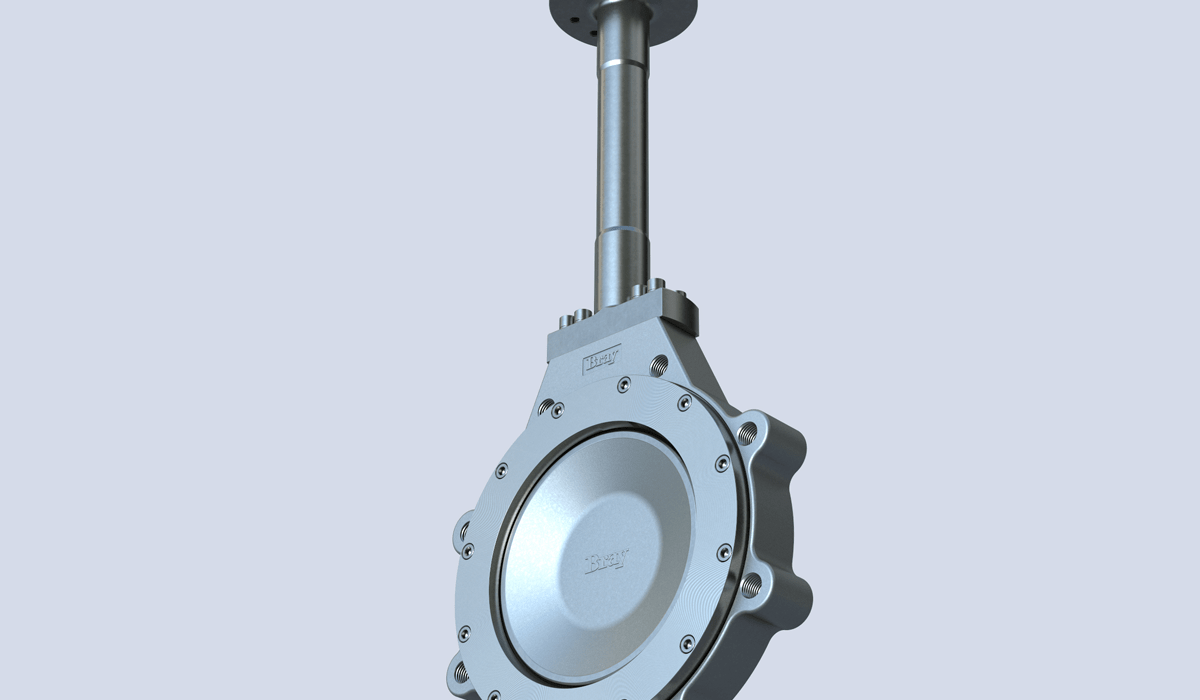

Saturated sodium chloride brine as used in the chlor-alkali process (approximately 310 g/L at 180°F). It's preparation involves numerous steps including treatment, filtration to remove minerals and unwanted impurities and ion exchange. Brine is extremely corrosive to metals, causing pitting and crevice corrosion, requiring valves that are engineered from corrosion resistant alloys or fluoropolymer's. Bray's PFA-lined Amresist™ line of butterfly and ball valves are a superior choice for brine. Engineered for continuous exposure to concentrated sodium chloride brine, Bray's PFA lined valves are inert to sodium chloride and also mitigate scaling.

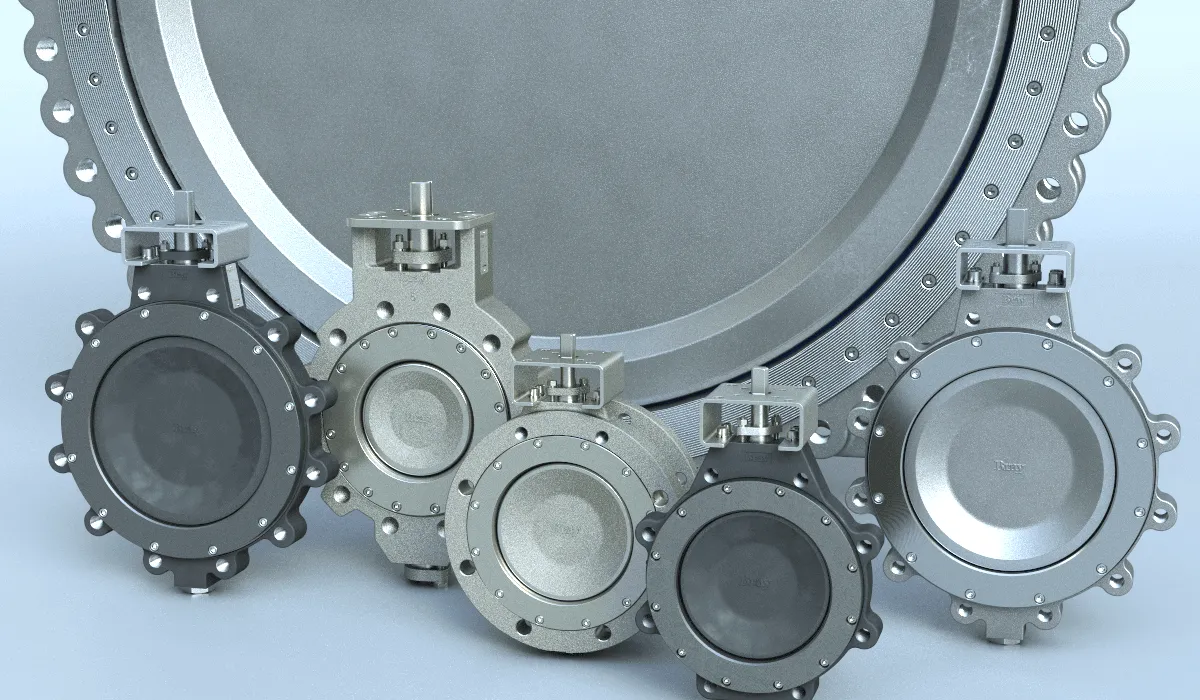

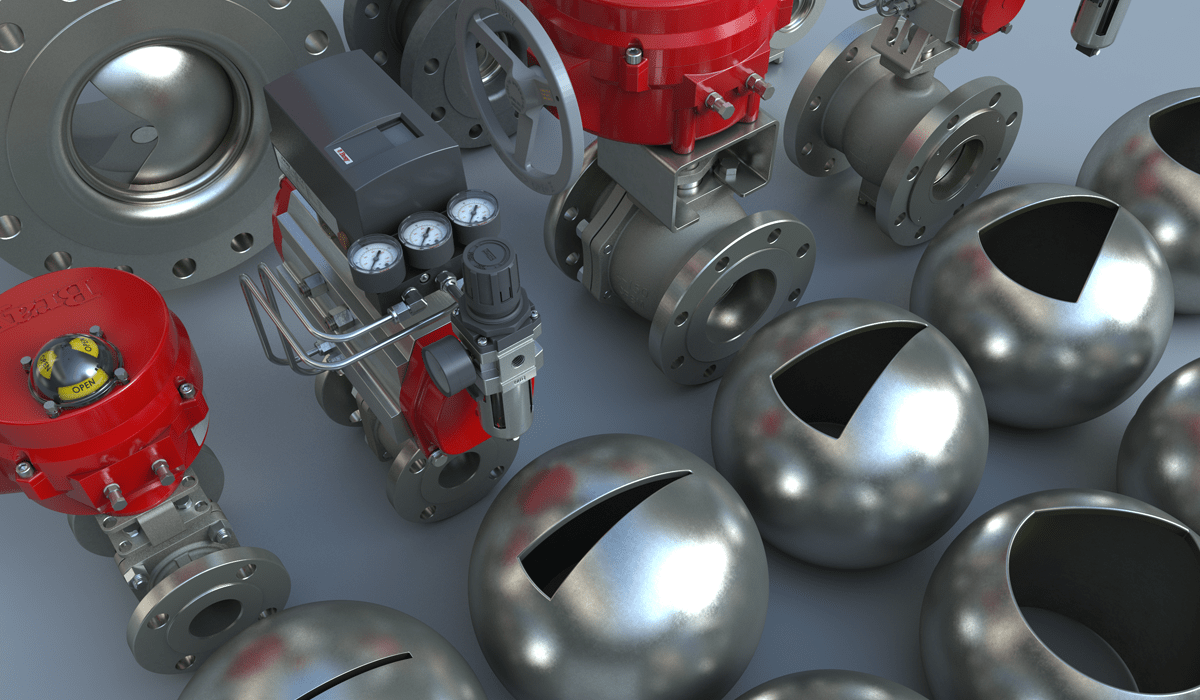

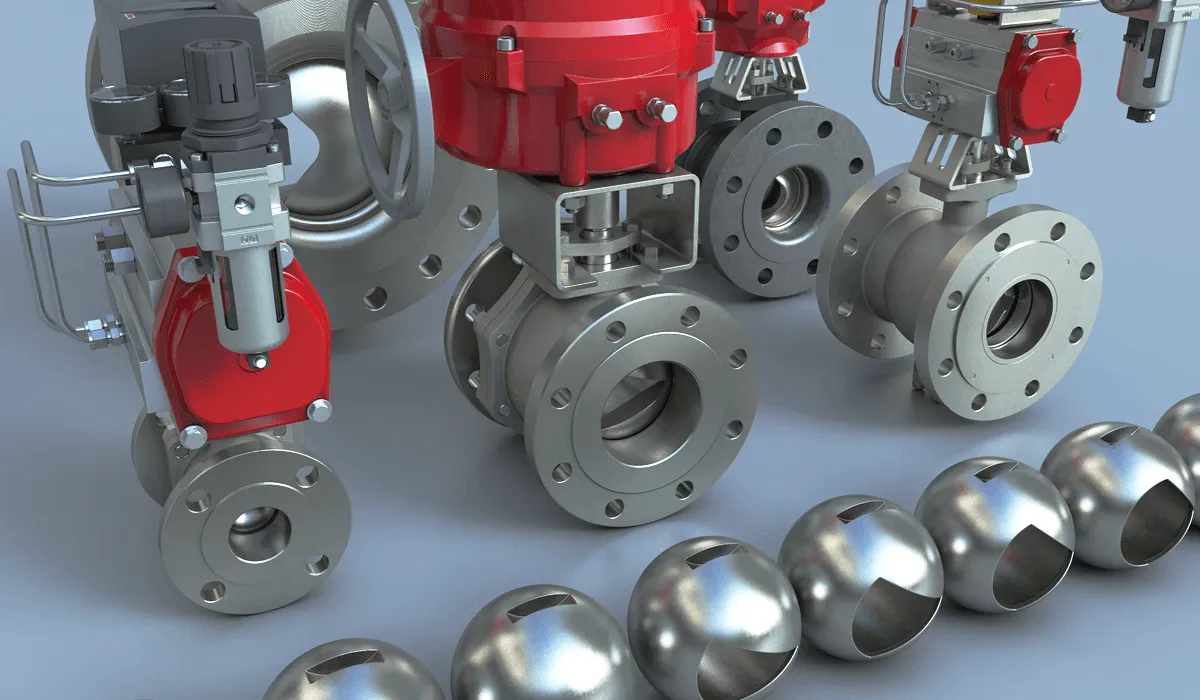

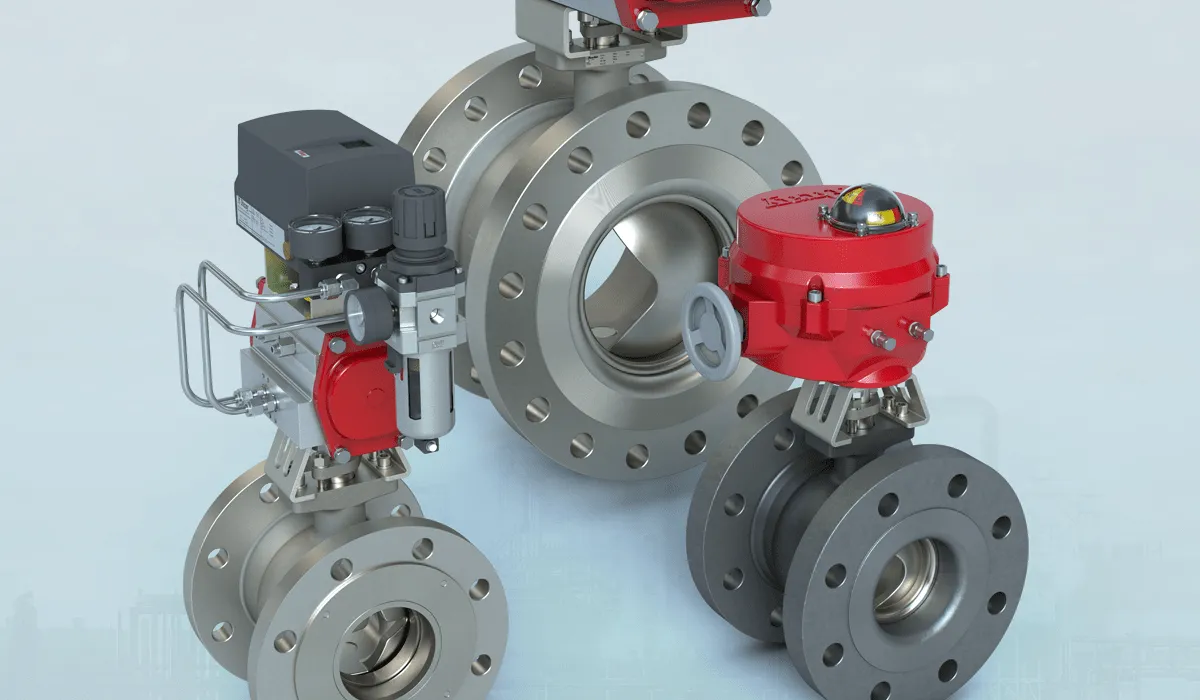

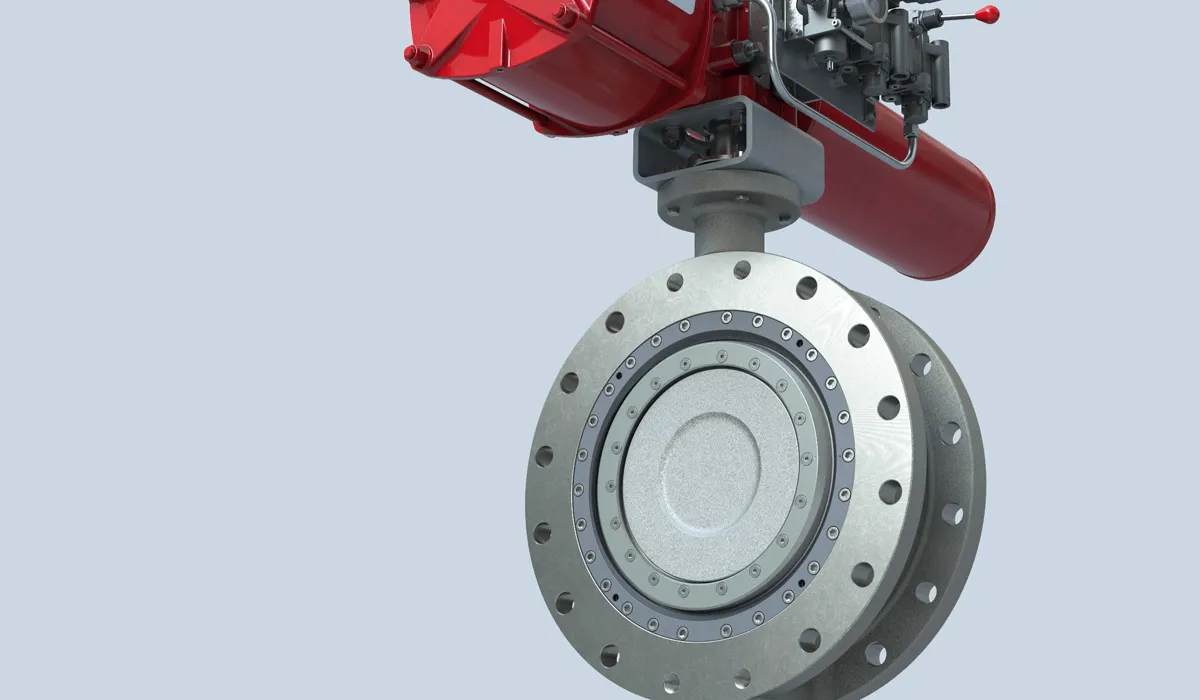

Bray manufactures a comprehensive portfolio of flow control solutions designed for both wet or dry (anhydrous) chlorine handling. Bray butterfly valves and vented ball valves are constructed of alloys specifically for dry chlorine service applications (less than 150 ppm water). These valves are designed to comply with recommendations from the Chlorine Institute Pamphlet 6, Piping Systems for Dry Chlorine. Wet chlorine is highly corrosive, forming hydrochloric and hypochlorous acids in the presence of moisture which will aggressively attack select stainless steels, Monel®, nickel alloys, copper, brass, bronze, and iron valves. Where ferric chloride or sodium sulfate may be present, these compounds can build up in parts of valves where there's low velocity. Ferric chloride and sodium sulfate in Chlorine Processing has a propensity to build up in parts of chlorine process valves. Bray PFA-lined Amresist™ butterfly and ball valves are engineered for wet chlorine service. Amresist valves are impervious to hydrochloric and hypochlorous acids and also prevent scale accumulation on the PFA lining, ensuring a tight seal.

Sodium Hydroxide (NaOH), also known as Caustic Soda, is produced during the Chlor-Alkali process. Caustic Soda is a commodity chemical and a strong alkali (base) that is highly corrosive to valves and other processing equipment and can cause serious harm to humans including chemical burns and blindness. Bray manufactures a wide variety of valves for caustic soda service at low and high concentrations where abrasive erosion is the primary concern and high concentrations. Bray PFA-lined Amresist™ butterfly and ball valves are inert against caustic soda, providing exceptional reliability, tight shutoff and long service life in caustic soda service.

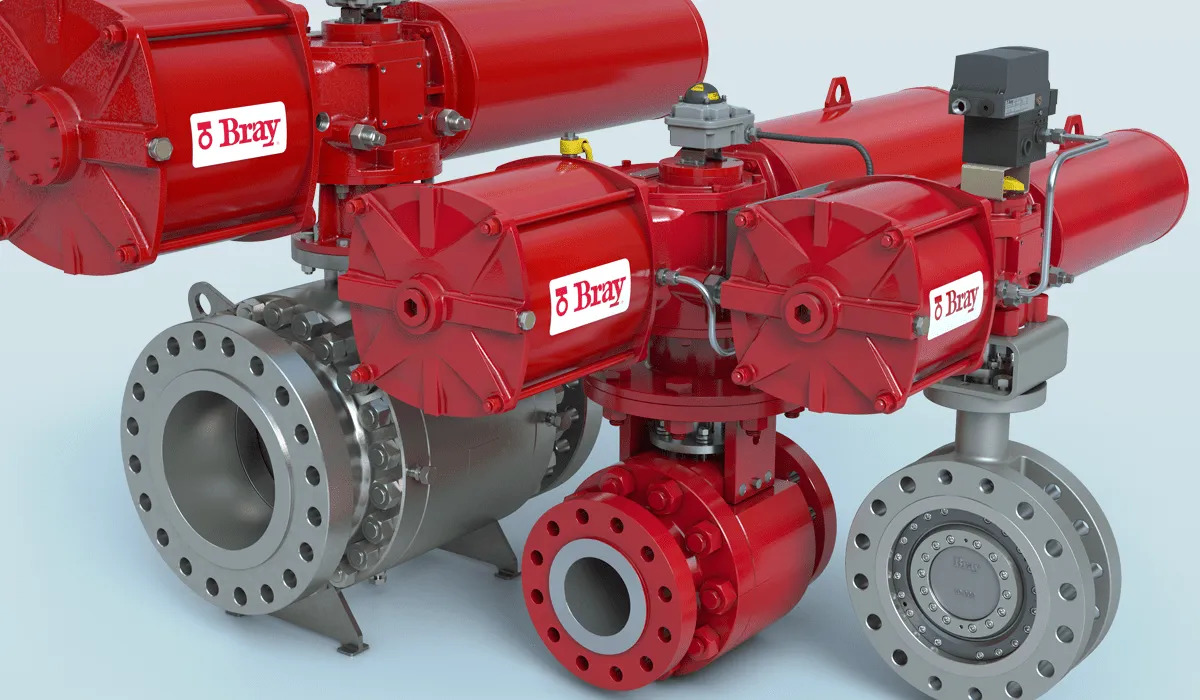

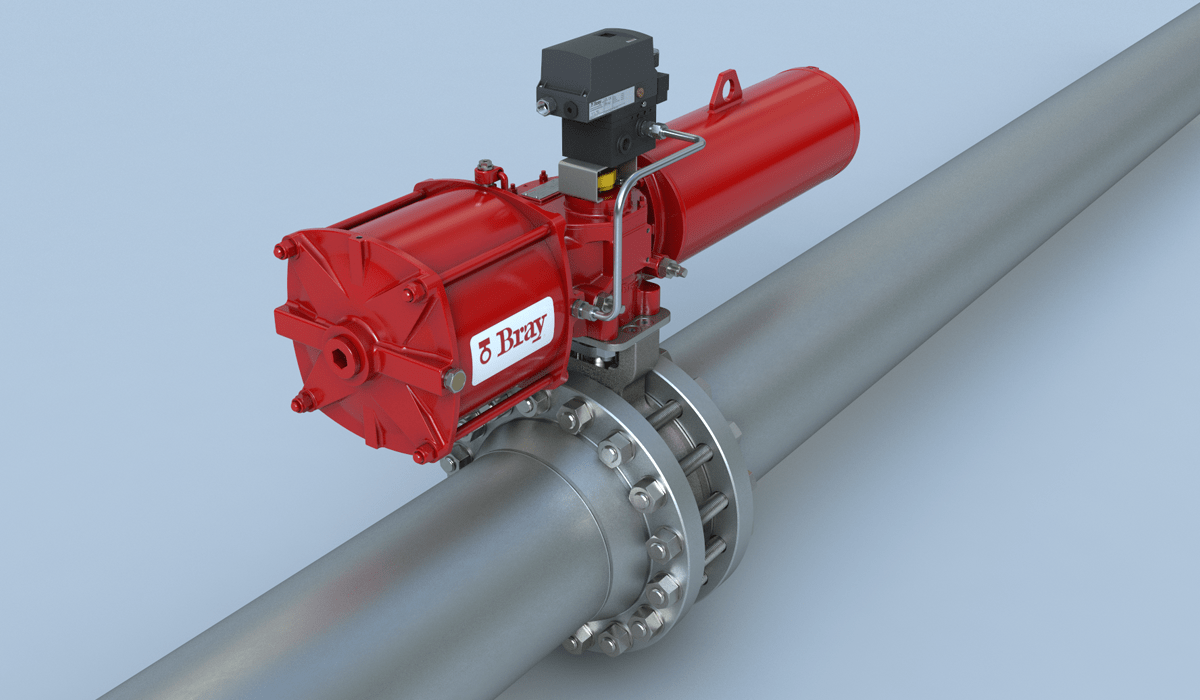

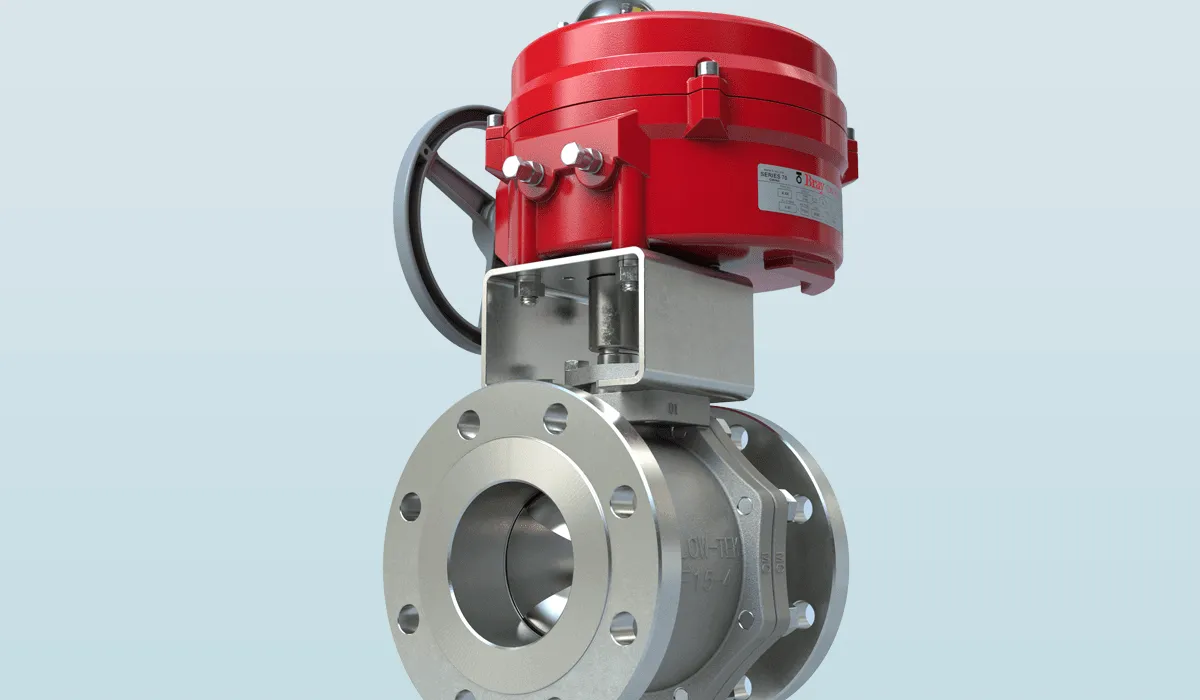

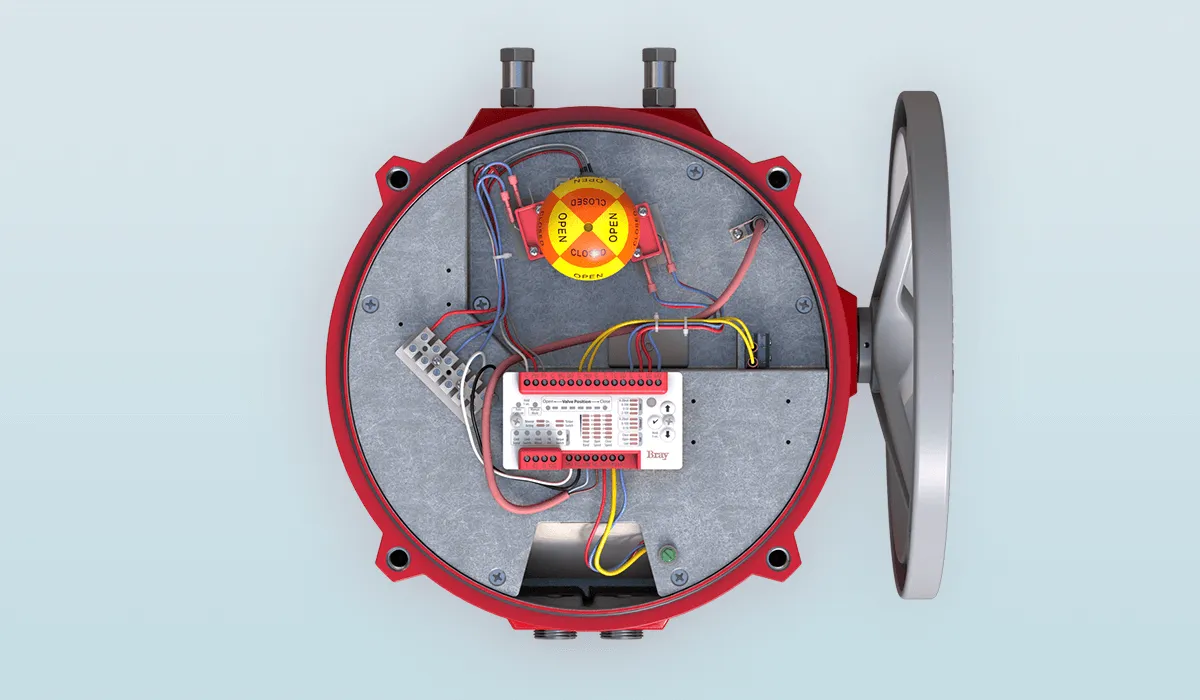

Hydrogen is a produced during the Chlor-Alkali electrolysis process. Valves for Hydrogen service also require special consideration. Hydrogen is highly flammable. Compressed hydrogen presents a risk of fire or explosion. Bray manufactures a variety of valves for hydrogen service including lined valves for areas that contain traces of chlorine and Fire-Safe valves. Bray API 607 fire safe valves, feature graphite packing seals and secondary metal seat sealing surfaces are engineered to maintain a seal during and after exposure to a flame.