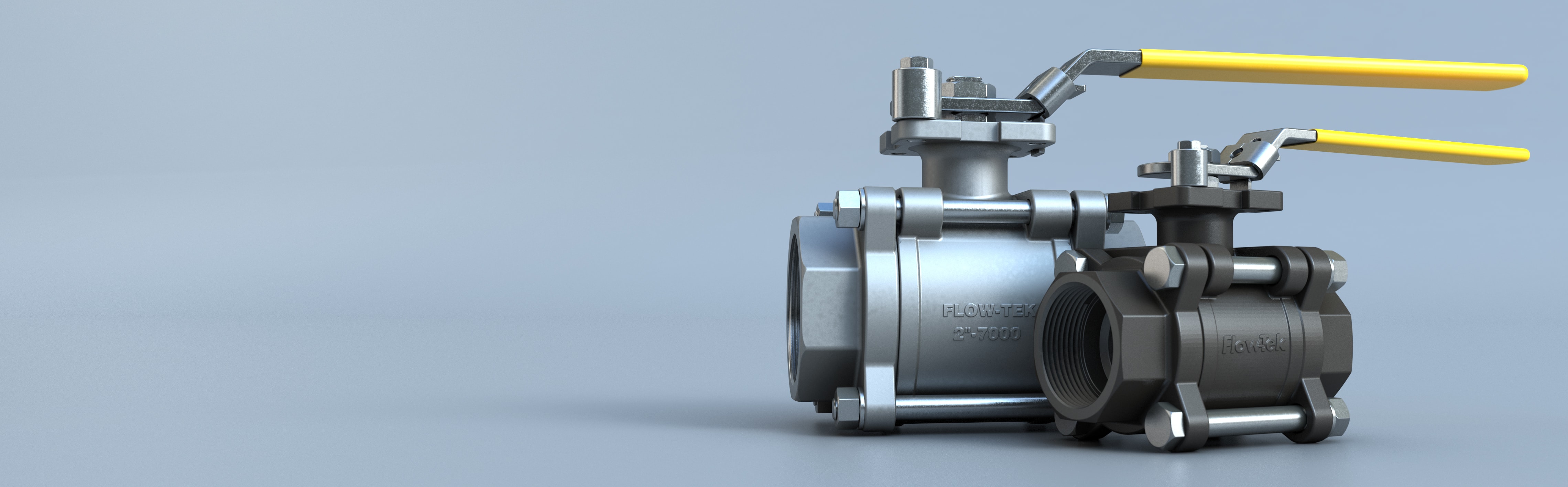

The Series 7000/8000 3-piece ball valves offer the highest flexibility in the Bray product line for selection of end connections, seat materials and three piece design. To meet customer demands for a valve with the widest possible range of applications, these valves can be fitted with control or tri-ported balls (for full cavity drainage), as well as cavity fillers for special service requirements.

The Series 7000/8000 is designed with extensive interchangeability of balls, stems, stem packing, handles and mounting hard- ware between valve sizes and series members. This system reduces parts inventory and maintenance costs.

The three piece body design allows the body to swing-out for ease of in-line maintenance. It also makes it possible to offer a wide variety of end connections.

3-Piece Ball Valve

Series 7000/8000

Size Range

NPS ¼ to 12 / DN 8 to 300

Temperature Range

-50°F to 550°F (-46°C to 287°C)

Maximum Allowable Operating Pressure

NPS ¼ to 4: 1000 psi CWP (DN 8 to 100: 69 Bar)

NPS 6 to 12: 400 psi CWP (DN 150 to 300: 27 Bar)

NPS 6 to 12: 400 psi CWP (DN 150 to 300: 27 Bar)

Specifications

3-Piece Ball Valve - Series 7000/8000

Size Range

NPS ¼ to 12 / DN 8 to 300

Body Materials

Series 7000: CF8M, Series 8000: WCB

Temperature Range

-50°F to 550°F (-46°C to 287°C)

Stem Materials

316 Stainless Steel

Maximum Allowable Operating Pressure

NPS ¼ to 4: 1000 psi CWP (DN 8 to 100: 69 Bar)

NPS 6 to 12: 400 psi CWP (DN 150 to 300: 27 Bar)

NPS 6 to 12: 400 psi CWP (DN 150 to 300: 27 Bar)

Seat Materials

Standard: RPTFE, Optional: TFM 1600, Tek-Fil®, UHMWPE, Cavity Fillers

Ball Materials

CF8M Stainless Steel

Body Style

3 Piece

Design Standard

MSS SP110

End Connections

Threaded ASME B1.20.1 NPT, Socket Weld ASME B16.11, Butt Weld MSS SP-72 /ASME B16.25, Flanged ASME Class 150, Extended Socket Weld, Extended Butt Weld

Testing Standard

API 598, MSS SP72

Ports

Full Port

Certifications

7000/8000: ATEX, CRN, PED, PE(S)R, TR CU, SIL

7000: NSF 61/372

7000: NSF 61/372

Face to Face

NPS ¼ to 4: Manufacturer Standard

NPS 6 to 12: ASME B16.10

NPS 6 to 12: ASME B16.10

Steam Rating

Up to 425 WSP

Fugitive Emissions Standard

EN ISO 15848-1