Ceramic Lined Butterfly Valve

Series 39

Specifications

Ceramic Lined Butterfly Valve - Series 39

Features & Benefits

-

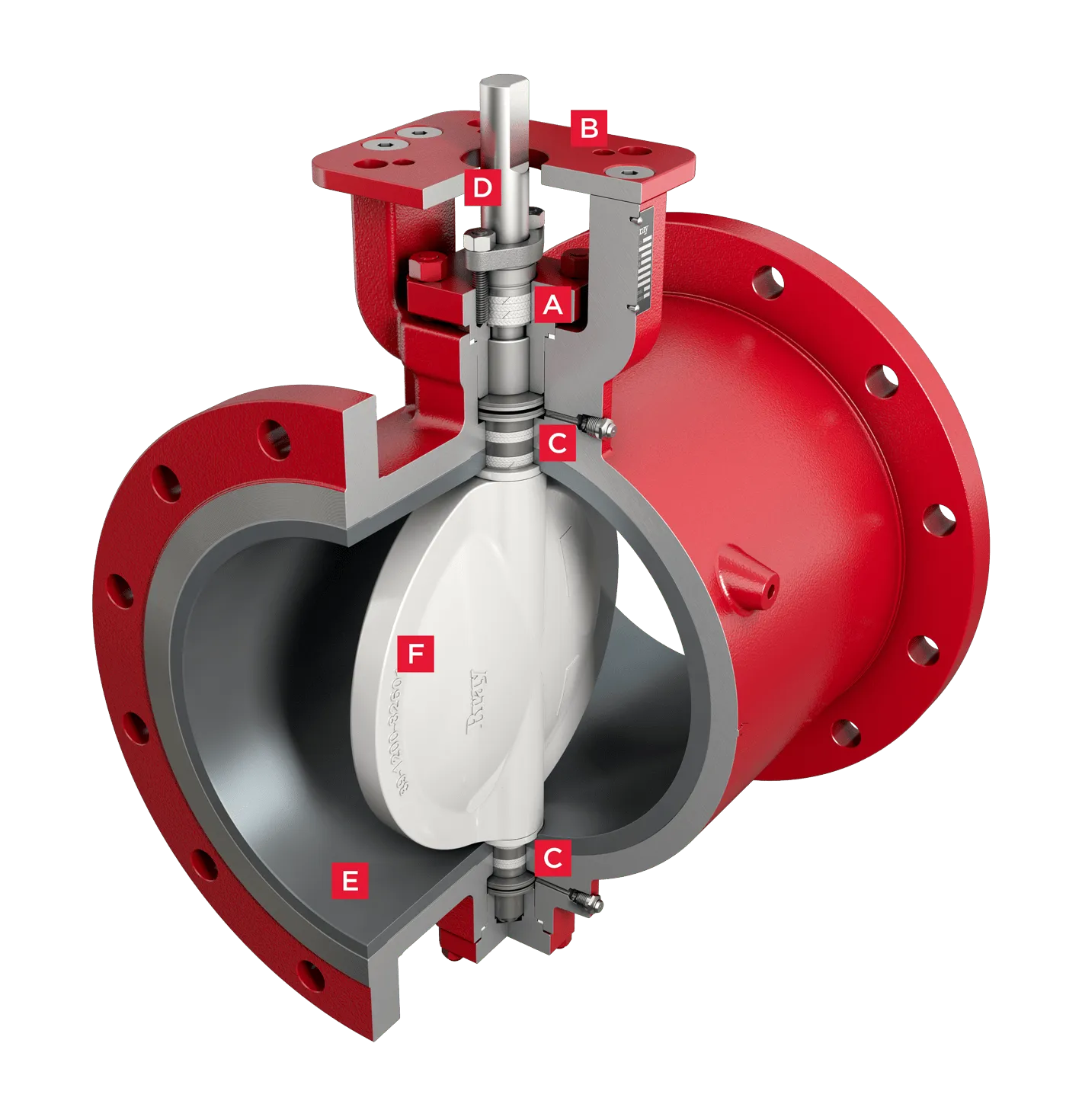

A. Adjustable Packing

The stem packing is easily accessible without requiring removal of the actuator.

-

B. Direct Mounting of Actuation

One-piece high strength 17-4PH stainless steel used in all sizes. Bray’s double-D stem design and ISO 5211 top plate allow for direct mounting of Bray actuators, reducing package complexity.

-

C. Engineered Stem Bearings

The upper stem bearing made from a 316 stainless steel outer shell and TFE/glass liner along with the lower stem bearing made of PSZ ceramic provide excellent resistance to corrosion and distortion caused by mechanical loading and high temperatures.

-

D. Blow Out Proof Stem

A retaining ring system is installed to ensure full retention of the stem in the unlikely event of internal stem failure.

-

E. Ceramic Liner

The diamond ground liner, made from Silicon Carbide Ceramic, has a high hardness rating and in most applications the liner will outlast the hard-wearing single offset disc. This design is long lasting with minimal maintenance cost, as only a few parts will ever require servicing.

-

F. Designed Control

The Series 39 is a control valve, the disc does not provide tight shutoff. The disc design maximizes flow with material options to minimize wear. This valve can in fact, swing through 360 degrees.