The Bray Series 765 bidirectional knife gate valve is designed for demanding slurry applications. Twin elastomer seats and push-through gate design facilitate self-cleaning and prevent media build up.

The durable ductile iron body is offered in a compact wafer style. When fully open, the valve is full bore, offering no resistance to line media.

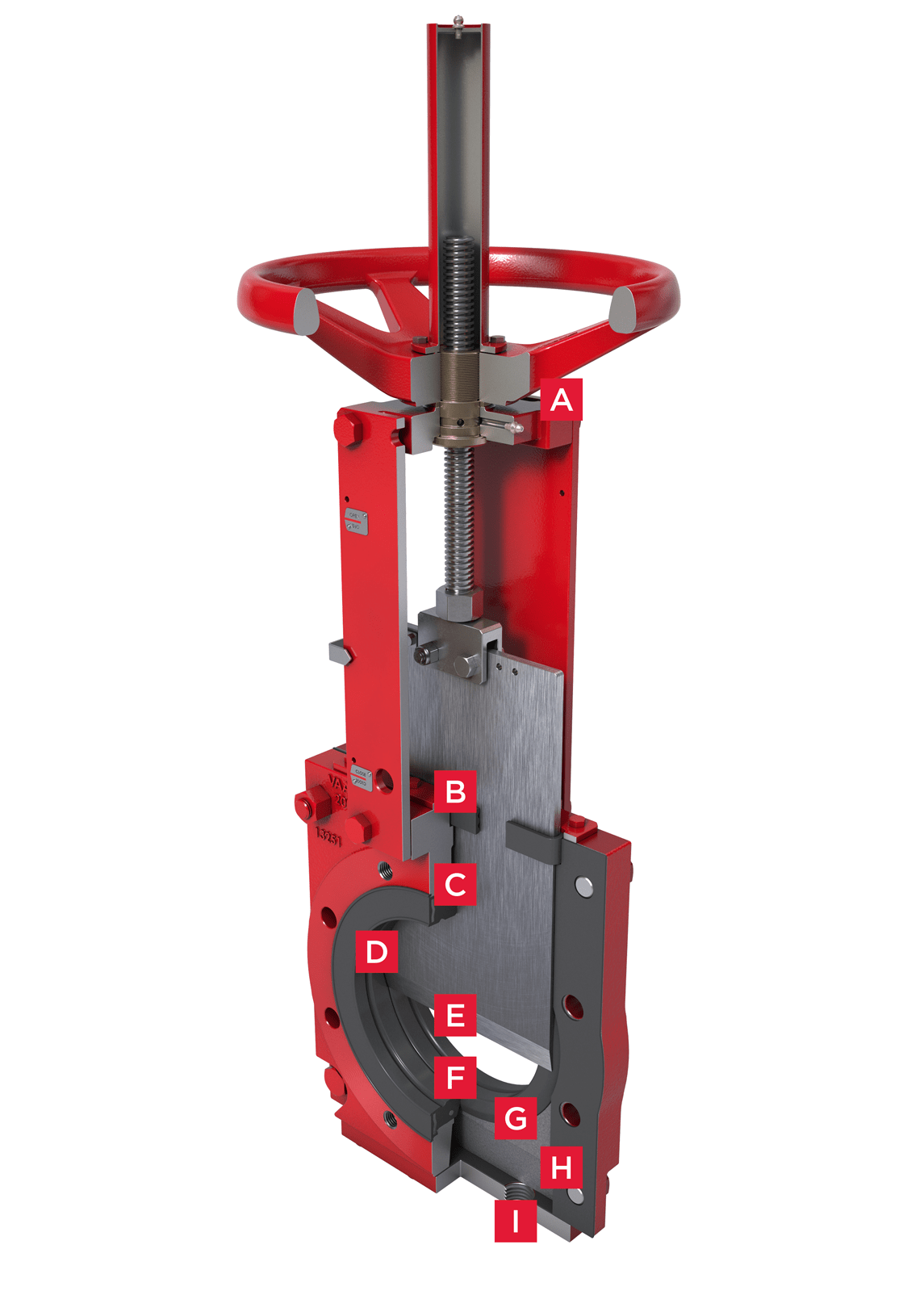

Bidirectional Knife Gate Valve

Series 765

Specifications

Bidirectional Knife Gate Valve - Series 765

EPDM: 248°F / 120°C

Features & Benefits

-

A

Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance.*

-

B

Self-adjusting secondary wiper seal extends gate life and prevents discharge from top of valve.

-

C

Metal-reinforced, elastomer sleeves provide energized, zero leakage shutoff in both directions.

-

D

In the open position, the energized sleeves shield all metal components from direct contact with the flowing process media.

-

E

Robust gate available in a wide range of corrosion resistant alloys to suit the application.

-

F

Unrestricted flow path with minimal pressure drop achieved through full port valve design for extended sleeve life.

-

G

Ample clearance for push-through allows complete gate closure.

-

H

Compact wafer body allows for easy installation and is drilled and tapped to ASME CL150 flange patterns as standard. Other drilling options available upon request.

-

I

Drain plate with tapped purge ports offered as an option, allowing for safe discharge of media and easy flush water connection.