The Bray Series 767 Knife Gate Valve is engineered specifically for high-pressure slurry applications. Equipped with advanced Bray SlurryShield Technology, this valve excels in abrasive & corrosive industrial environments, ensuring

optimal performance.

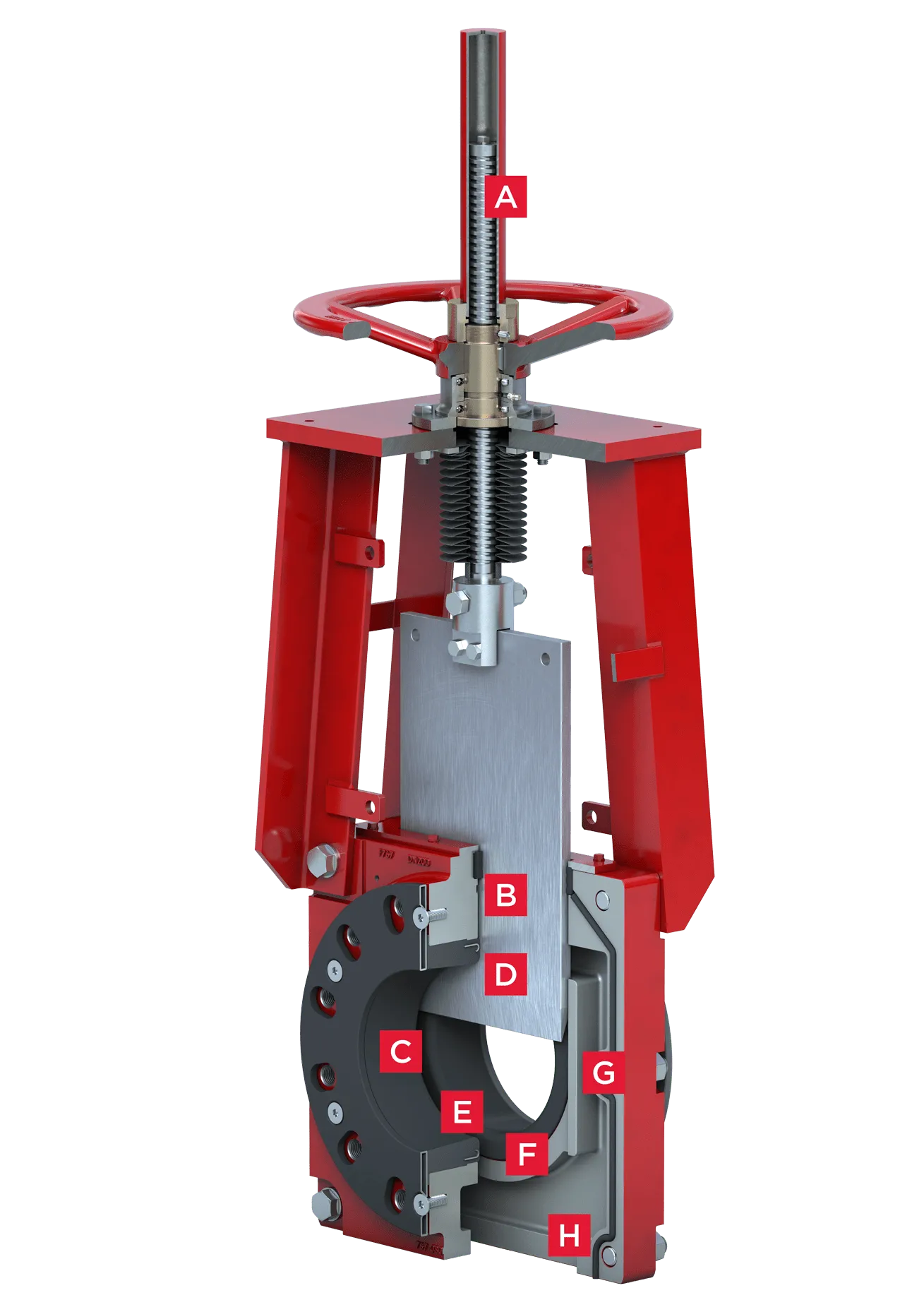

Constructed from durable cast WCB, the valve body showcases durability and extended lifespan. Its two-piece bolted wafer style design facilitates easy installation and maintenance while upholding high-performance standards.

Featuring a push-through gate design, the Series 767 ensures bidirectional zero leakage shutoff, making it ideal for use across diverse industries including Mining, Pulp & Paper, General Industry, Power, and Cement. The two eslastomer

sleeves are replaceable components of the assembly and enable the valve body, gate and topworks to have a long life cycle. Maintenance can be preformed onsite and customer does not have to send the asset away for extended periods of down time.

Available with natural rubber or EPDM sleeves, the valve provides resistance to abrasion and corrosion. Choose from a variety of gate materials including 316 stainless steel, 2205 duplex stainless steel, and 17-4 stainless steel to meet different

pressure rating requirements.

Features

- Protective stem cover is standard increasing cycle life in hazardous environments.

- Fully encapsulated J-ring providing sleeve reinforcement and memory assist, guaranteeing bidirectional zero leakage performance. Designed specifically to operate in higher pressure ratings.

- In the open position, the energized sleeves shield all metal components from direct contact with the flowing process media.

- Change to Gate: Robust gate designed for high pressure slurry applications and available in a wide range of corrosion resistant alloys.

- Full port design provides unobstructed flow path, extending sleeve life and minimizing pressure drop across the valve.

- Designed with ample clearance for gate & media push-through allowing complete gate closure.

- Flanged two-piece bolted body allows for easy maintenance and is drilled and tapped to ASME CL300 flange patterns as standard. Other drilling options available upon request.

- Optional bottom flush plate with tapped ports, allowing for safe discharge of media and easy flush water connection.

.webp?sfvrsn=8f9720cf_1)

.webp?sfvrsn=f84f16e5_1)